Introduction to Ultrasonic Reactor

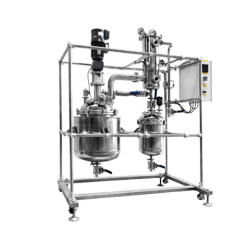

An ultrasonic reactor refers to a kind of reactor utilizing the ultrasonic as an enhancement aid. Equipped with the ultrasonic device, the reactor can save solvent, speed up the reaction process, and enhance both the extraction rate and the dissolution rate.

What is an Ultrasonic Reactor Used for?

An ultrasonic double layer glass reactor is an ideal equipment for lab-scale and pilot tests, biopharmaceutical, new drug research and development and new material synthesis. It is primarily used in small chemical industry, petroleum, metallurgy, coal, electronics, building materials, light industry and other fields, or the medium and small scale production.

What are Advantages of an Ultrasonic Reactor?

An ultrasonic double layer glass reactor is independently researched and designed, while it imports international advanced technology. It can improve the dissolution rate and speed up the reaction process, and efficiently reduce reaction failure caused by uneven dispersing of reactants concentration. Furthermore, it serves as a green, safe and simple descaling method, which is capable of effectively removing obstinate residues inside the kettle wall.

Regular Reactor VS. Ultrasonic Reactor

Based on a regular reactor, an ultrasonic reactor is equipped with the ultrasonic device. It can greatly improve the dissolution rate, speed up the reaction process and effectively reduce the reaction failure caused by uneven dispersing of reactants concentration. It is capable of effectively removing obstinate residues inside the kettle wall as well.

Precautions for Using an Ultrasonic Reactor

- Don’t casually move driving power and directly plug in or out power supply during the operation. In case of any abnormal sound or indication, switch off the driving power immediately and troubleshoot the failure cause to avoid equipment damage.

- It is a normal phenomenon to have some slight cavitation on the surface of tool heads after products go through the factory test.

- There are precision components carrying high voltage in the ultrasonic device. Don’t disassemble or assemble without permission or under no guidance of professional personnel.

- Pay attention to the case temperature of the main engine when it is used for a long time. The forced dissipation is required when the temperature exceeds 45℃ in order to ensure the normal operation of the main engine.

- Remove the blue plastic film before use to ensure the heat dissipation.

- It is strictly prohibited to start for a long time without load, and the no-load start shouldn’t exceed 15 seconds.

[title text=”Related Products” tag_name=”h2″ color=”rgba(32, 163, 219, 0.81)”]

[title text=”Related Posts” tag_name=”h2″ color=”rgba(32, 163, 219, 0.81)”]

https://www.rotovap.cn/glass-reactor/1402.html

https://www.rotovap.cn/glass-reactor/1038.html

https://www.rotovap.cn/glass-reactor/1621.html