The falling film evaporators are greatly well-received in many industries as a high efficient evaporation and concentration equipment. However, when the falling film evaporators are used, there will be some malfunctions sometimes. Once it happens, what we should do is to find out problems and solutions as soon as possible. The following maybe helpful.

Falling Film Evaporators’ Troubleshooting

Possible Problems:

- The control of the amount of alkali is not good, especially the flow interruption caused by the cavitation of the concentrated alkali pump, which has a great influence on the falling film tube.

- Insufficient compensation of falling film tube causes the deformation of falling film tube. Due to insufficient compensation of the expansion joint, the falling film tube installed at the expansion joint is unstable, which causes damage to the expansion joint.

- The insulation of the falling film evaporator system also has a great influence on the falling film tube. Heat loss caused bypoor insulation can affect the heat transfer effect of the falling film evaporator. If the alkali temperature is raised by increasing the molten salt temperature, the falling film tube will also be damaged.

Several Solutions:

- The baffle is added at the alkali inlet of the distributor to increase the uniform distribution of the lye and reduce the occurrence of drywall.And strictly control the amount of alkali to maintain the uniformity of the alkali flow, including the control of the cavitation of the concentrated alkali pump. The alkali valve of the falling film tube is installed with a nickel base valve to reduce leakage.

- The original expansion joint is modified to increase the expansion joints in an appropriate amount.A temperature measurement system is added at the molten salt outlet to detect the smooth flow of the molten salt at any time. If there is a blocked molten salt, the corresponding alkali inlet valve can be closed.

- A conical baffle should be added at the inlet of the molten salt to reduce the effect of molten salt on the falling film tube.

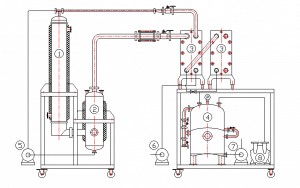

Working Principle of a Falling Film Evaporator

The working principle of falling film evaporators can be described as follows. The liquid is added to the upper tube of the heating chamber of the falling film evaporator. Through the liquid distribution and film forming device, it is evenly distributed into the heat exchange tubes. Under the action of gravity and vacuum induction and air flow, it forms a uniform film from the top to the bottom. During the flow, it is heated and vaporized by the shell-side heating medium. The generated steam and the liquid phase enter the separation chamber of the evaporator. The vapor-liquid is sufficiently separated, and the steam enters the condenser for condensation (single-effect operation) or enters the next-effect evaporator. The medium is heated to achieve multi-effect operation, and the liquid phase is discharged from the separation chamber.

Methods of Improving Its Efficiency

- Control the amount of mother liquid added in the appropriate range: The attention should be paid to the amount of circulation for falling film evaporators with various evaporation capacities in order to ensure that the liquid film can flow steadily and evenly in the heating tubes.

- Control the heat flow intensity: It is necessary to control the steam pressure and ensure the steady steam velocity as well as discharge the non-condensable gas continuously in order to obtain the stable heat flow intensity.

- Selection of distributors on the falling film tubes: Distributors act as extremely important components in a falling film evaporator. The form of liquid film depends on distributors. So the selection of distributors is pretty essential. It is required to clean the distributors of falling film evaporators regularly.

[title text=”Related Products” tag_name=”h2″ color=”rgba(32, 163, 219, 0.81)”]

-

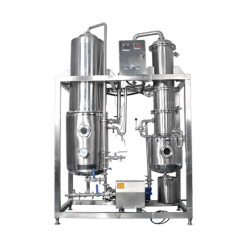

FFE 200L Single-Effect Falling Film Evaporator

Read more -

20L Falling Film Evaporator

Read more -

50L Single-Effect Falling Film Evaporator

Read more -

S212-200L Double-Layer Glass Reactor

Read more -

DLSB-200/40 Low Temperature Coolant Circulation Pump(Chiller)

Read more -

R-1020 Double Cold Trap Rotary Evaporator

Read more