Construction and Operation of Evaporators

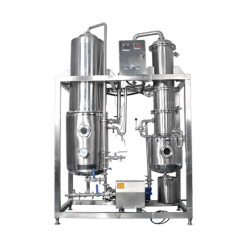

Due to the need of substance’s extraction and concentration in industrial field, there are so many types evaporators in marketing. Even though there are so many different types of evaporators, their construction are very similar. Generally, the construction of evaporators includes a heat exchanger to heat the sample substances, a condenser to condensate the extracted substances, a separator to separate the mixed liquid and extracted substances, and a vacuum pump to provide a vacuum environment for the whole operating equipment.

The correct operation of evaporators is very essential for users’ safety and the quality of resultant substance. So next let’s go through the correct operation together:

(1) Correctly and reasonably open and close the evaporator according to the operating procedures. Enterprises should correctly select and rationally allocate equipment according to the production process and process characteristics, as well as the process intensity, so that they can coordinate the process performance and production capacity.

(2) Properly arrange production tasks. Different MVR evaporator devices have different process performance and load capacity. The enterprise shall arrange the production tasks according to the process performance of the evaporator equipment, and formulate the labor quota according to the load capacity (work efficiency) of the evaporator equipment, so that the process performance and load capacity of the equipment are compatible with the production tasks. And it is strictly forbidden to use the “roughly use the fine machines” and overloaded.

(3) Provide good working conditions. All evaporator equipment is designed and manufactured according to certain scientific and technical principles in order to meet the actual production needs, and requires working under certain working conditions. The reliability of the equipment is also achieved under certain working conditions. Therefore, the creation of good working conditions is an important condition for ensuring the normal operation of the evaporator equipment, prolonging the service life and ensuring safe production.

Practical and Economic Benefits of Falling Film Evaporators

The falling film evaporator is very popular in industrial, chemical, biochemical, food and other fields, because it has high efficiency, practical and economic benefits. The practical and economic benefits can be concluded as follows:

(1) The falling film evaporator is a concentrating device belonging to the natural circulation, and the heat transfer efficiency is very high during use, which saves a lot energy.

(2) Since the evaporation temperature of the falling film evaporator is relatively low, during operation, a part of the secondary steam passes through its hot press pump and is re-inhaled into the next heater, which forms a recyclable utilization.

(3) The falling film evaporator can use the disc or tube bundle dryer exhaust gas and other low calorific value heat sources as the heat source of the evaporator to a certain extent, so that the amount of steam can be greatly reduced,which can achieve the effect of energy saving. When the waste steam has a sufficient supply, it is possible to use no raw steam, so that significant economic benefits can be achieved.

[title text=”Related Products” tag_name=”h2″ color=”rgba(32, 163, 219, 0.81)”]

-

FFE 200L Single-Effect Falling Film Evaporator

Read more -

20L Falling Film Evaporator

Read more -

50L Single-Effect Falling Film Evaporator

Read more -

S212-200L Double-Layer Glass Reactor

Read more -

DLSB-200/40 Low Temperature Coolant Circulation Pump(Chiller)

Read more -

R-1020 Double Cold Trap Rotary Evaporator

Read more

[title text=”Related Posts” tag_name=”h2″ color=”rgba(32, 163, 219, 0.81)”]

https://www.rotovap.cn/falling-film-evaporator-problems/3661.html

https://www.rotovap.cn/falling-film-evaporator-problems/3543.html

https://www.rotovap.cn/falling-film-evaporator-problems/3579.html

https://www.rotovap.cn/falling-film-evaporator-problems/3160.html

https://www.rotovap.cn/falling-film-evaporator-problems/3693.html