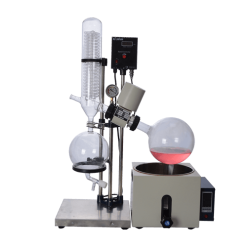

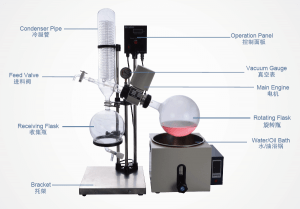

Parts of a Rotary Evaporator and Their Functions

- In the evaporation part, the evaporation flask rotates at a constant speed to facilitate evaporation by enlarging evaporation area. In this part, there is a heating mantle to heat materials in the evaporation flask, and get materials evaporated. What’s more, the evaporation flask will keep rotating at a constant speed to get a bigger evaporation area, in order to get materials evaporated more quickly.

- The vacuum pump removes gas from the sealed equipment to leave behind a partial vacuum, in order to create a continuous feed system and keep the purity of extracted solvents. It provides the rotary evaporator equipment a vacuum environment. This vacuum environment has two functions: firstly it maintains a reduced pressure environment required by a rotary evaporator; secondly, the pressure difference between a vacuum environment and atmosphere pressure creates a automatic feeding system.

- The condensing part cools the equipment and turns extracted solvents from gas into liquid. In this part, the gas-phase materials can get condensed by condensing tubes, and then they will be turned into liquid-phase materials. After condensing materials, it is more convenient to collect materials for users.

- Then the solvents liquid goes into the receiving flask for users to collect. This part is about the final step of the working process. In this part, the liquid-phase materials will be transferred and collected here. And then the users will take the receiving flask down very easily.

How does a Rotary Evaporator Work?

A rotary evaporator is used to extract solvents from liquid mixtures by evaporation in chemical, biochemical and other fields. The working process of a rotary evaporator can be roughly described below. At first, samples are placed in the evaporation flask. With the evaporation flask rotating at a constant speed, there will be a thin film of sample inside the evaporation flask, which facilitates evaporation rate. Then extracted solvents are transferred into condenser and condensed into liquid from gas. This whole process takes place in a partial vacuum created by the vacuum pump.Functions of a Rotary Evaporator

A rotary evaporator is an essential separation equipment, which can remove a valtile solvent from a liquid mixture through evaporation and condensation. For example, a rotary evaporator can be used to remove ethanol from the mixture of ethanol and cbd oil in order to improve the purity of cbd oil. Also, it can be used to remove water within fruit juice, in order to make the fruit juice have a higher concentration. It can be seen that a rotary evaporator has a great number of functions.Is a Rotary Evaporator Distillation?

In essence, a rotary evaporator can be regarded as a kind of reduced pressure distillation. As it is mentioned above, the entire working process of a rotovap takes place in a partial vacuum or reduced pressure environment created by the vacuum pump. The round-bottom flask containing the solution is placed in the water bath of the equipment, and rotated when the system is partially evacuated by a vacuum pump.How to Troubleshoot a Rotary Tablet Press?

The rotary tablet press serves as the main device for producing tablets in pharmaceutical field and even other fields. It features compact structure, stable performance,

Diaphragm Vacuum Pump VS. Rotary Vane Vacuum Pump

Vacuum pumps are widely applied in many industries with the deep development of modern science and technology. They can be used for scientific research, production

What is the Primary Advantage of a Rotary Evaporator over Distillation?

Rotary evaporators are common laboratory equipment mainly composed of a motor, a rotating flask, a water or oil bath and a condenser tube and other

What are Applications of a Rotary Evaporator?

What is a Rotary Evaporator? A rotary evaporator is an indispensable equipment for the processes of evaporation, concentration, crystallization, drying, separation, and solvent recovery in

How to Use a Rotary Evaporator?

A rotary evaporator (rotovap or rotavap) refers to a kind of equipment for solvent evaporation under reduced pressure, which is composed of a vacuum system, a

Why do We Use Rotary Evaporator?

[ux_image id=”24533″ height=”62%” margin=”-40px 0px 0px 0px” lightbox=”true” caption=”true” image_overlay=”rgba(0, 0, 0, 0.1)” image_hover=”zoom” image_hover_alt=”zoom-long”] [gap] As an essential and common lab equipment, a rotary