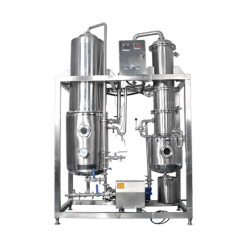

What is a Falling Film Evaporator?

A falling film evaporator refers to a concentration and evaporation device used in industries. It is applicable for the concentration and evaporation of water, organic solvents and solutions in the pharmaceutical, food, chemical, light industries and other industries, and it is especially suitable for heat sensitive materials and materials with higher concentration and higher viscosity. The equipment is continuously operated under vacuum and low temperature conditions, with high evaporation capacity, energy conservation, low operating cost. It can ensure that the material is invariable during the evaporation.

Questions on Falling Film Evaporator

1. The falling film evaporator suddenly stops evaporating, and then the evaporating output concentration is getting lower. This type of failure is generally a slow process, and the main cause of such failure is the loosening or cracking of the joint between the upper and lower tube sheets and the falling film tube of the falling film evaporator.

2. The material goes out of the falling film evaporator. This kind of failure means that the material enters the shell side of the falling film evaporator (or the shell side of the condenser). During the evaporation process, if the material enters the liquid in the shell side (in the lower part of the effect body), the sight glass can be observed or detected by the sight glass.

3. The production ability of falling film evaporators is gradually reduced. This kind of failure generally occurs in the process of long-term use, for two reasons: Firstly, the vacuum attitude of the vacuum system is reduced. The second reason is the external fouling of the condenser and the falling film tube (increasing the heat transfer resistance).

4. The falling film evaporator system has a reduced vacuum. The main reason for the sudden decrease in the degree of vacuum is that the supply of cooling water is insufficient and the water temperature is too high; the vacuum pump overflow is severely corroded, the end of the impeller is too large, the suction is insufficient, and the system has a leak.

Tips on Falling film evaporator

1. When the evaporator is working continuously for a certain period of time, it must be shut down for cleaning. Otherwise, it is even difficult to clean thoroughly during cleaning, which ultimately affects product quality.

2. The falling film evaporator is characterized by a short time for the liquid to be heated in the evaporator, and reducing the heating time can undoubtedly keep the beneficial elements in the liquid from being destroyed, thereby ensuring the quality of the product. The splitting is because the peripheral wetting amount of the falling film tube is insufficient. In order to prevent the scaling coking acceleration or the dry wall phenomenon, a split method is adopted to increase the peripheral wetting amount of the falling film tube.

[title text=”Related Products” tag_name=”h2″ color=”rgba(32, 163, 219, 0.81)”]

-

FFE 200L Single-Effect Falling Film Evaporator

Read more -

20L Falling Film Evaporator

Read more -

50L Single-Effect Falling Film Evaporator

Read more -

S212-200L Double-Layer Glass Reactor

Read more -

DLSB-200/40 Low Temperature Coolant Circulation Pump(Chiller)

Read more -

R-1020 Double Cold Trap Rotary Evaporator

Read more

[title text=”Related Posts” tag_name=”h2″ color=”rgba(32, 163, 219, 0.81)”]

https://www.rotovap.cn/falling-film-evaporator-problems/3543.html

https://www.rotovap.cn/falling-film-evaporator-problems/3579.html

https://www.rotovap.cn/falling-film-evaporator-problems/3160.html

https://www.rotovap.cn/falling-film-evaporator-problems/3693.html

https://www.rotovap.cn/falling-film-evaporator-problems/3168.html

https://www.rotovap.cn/falling-film-evaporator-problems/3647.html