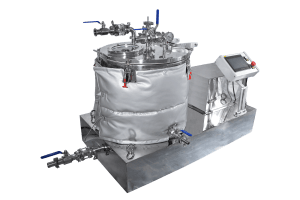

What is an Industrial Centrifuge?

An industrial centrifuge is the ethanol extraction equipment, which is a device that utilizes the centrifugal force to separate liquid and solid particles or components of a liquid mixture. It is initially used for separating the compositions of milk, and now expands into the scientific, medical and other fields. It is a extremely popular and effective solid-liquid extraction technique, and widely used in many fields, such as the chemical engineering, petroleum, food processing, pharmaceutical, mineral processing, carbon, water treatment, nuclear energy industry and shipbuilding, and other fields.

How does an Industrial Centrifuge Work?

The working process of industrial centrifuges can be roughly concluded as follows. The centrifuge has a cylinder(drum) that rotates at a high speed, which is usually driven by an electric motor. After the suspension (or emulsion) is added to the drum, it is rapidly driven to rotate at the same speed as the drum, and the components within the mixtures are separated under the function of the centrifugal force and discharged separately. Generally, the higher the drum speed is, the better the separation will be. When the suspension containing fine particles is left still, the suspended particles gradually sink due to the action of the gravitational field. The heavier the particles are, the faster they sink.

What are Types of Industrial Centrifuges?

Based on different classification standards, centrifuges can be classified into different types, as follows:

- In terms of the separation methods, industrial centrifuges can be classified into the decanter centrifuge and the filter centrifuge.

- According to the various structures, there’re five kinds of industrial centrifuges, which are the plate centrifuge, the three-foot centrifuge, the tubular centrifuge, the disc centrifuge and the horizontal screw decater centrifuge.

- Based on the unloading ways, industrial centrifuges can be classified into the upper discharge centrifuge, the lower discharge centrifuge and the screw discharge centrifuge.

- Considering the production capacity, industrial centrifuges can be classified into the small centrifuge and the large centrifuge.

- In terms of the purposes, industrial centrifuges can be classified into the biological centrifuge, the pharmaceutical centrifuge, the chemical centrifuge and other centrifuges.

Selection Guide for Industrial Centrifuges

Essentially, the selection of industrial centrifuges is to find a specific device that can meet the technological requirements among various centrifuges according to the physical parameters and technological requirements of materials. It is required that the technology, equipment and engineering technicians can cooperate with each other well. The physical parameters related to the selection of centrifuges mainly consists of the solid phase concentration of suspensions, solid particle size range, specific gravity difference between solid and liquid phases and liquid phase concentration. The separation purposes should be considered as well. The various purposes lead to different selections of machine models.

Selection Principles of Industrial Centrifuges:

- Have a comprehensive analysis and understanding of the solid-liquid separation process system;

- Have a full understanding towards the properties of separated materials;

- It should satisfy the separation tasks and requirements, such as the treatment capacity per unit time, reacovery rate of solid and liquid phases and other requirements.

- The economical principle should be taken into consideration as well.

Selection Guide of General Centrifuges:

- The ordinary three-foot centrifuges can be selected for general materials and less budgets.

- The scraper centrifuges can be selected for large treatment capacity and low labor cost.

- The horizontal scraper centrifuges can be selected for starch materials.

- The hanging bag centrifuges can be selected for loose and large particles;

- The sedimentation centrifuges can be selected for materials with high viscosity and fine solid particles.

- The anti-explosion centrifuges should be selected in the inflammable and explosive occasions.

[title text=”Related Products” tag_name=”h2″ color=”rgba(32, 163, 219, 0.81)”]

[title text=”Related Posts” tag_name=”h2″ color=”rgba(32, 163, 219, 0.81)”]

https://www.rotovap.cn/blog/5985.html

https://www.rotovap.cn/blog/5997.html

https://www.rotovap.cn/blog/5989.html