Description

PP series industreal centrifuge can be used to extract and filter centrifuges for cannabis and other plants. The series of centrifuges extract the active ingredients in plants through a built-in program, which is single-handed, easy to use and large in capacity.

The centrifuge is a general-purpose mechanical product for gap operation. It is suitable for separating suspensions containing solid phase particles which are greater than or equal to 0.01 mm, such as the separation of granular, crystalline or fibrous materials, and also the dehydration of textile. Although the PS type is manually unloaded, it has the advantages that the filtration time can be controlled at any time, and the filter residue can be sufficiently washed, and the solid phase particles can’t be destroyed. The part of the centrifuge exposed to the material is made of stainless steel. Therefore, the centrifuge is widely used in chemical, pharmaceutical, food, light industries and other fields. At the same time, special centrifuges can be produced according to the needs of users.

Working Principle

The centrifuge is a machine that separates solid and liquid components in a suspension and an emulsion by using centrifugal force. Under the function of the centrifuge, the liquid contained in the material is pumped to the inner wall of the outer casing through the filter medium and the hole in the wall of the drum. After collection, the liquid is discharged from the filtrate outlet, and the solid phase is left in the drum. The separation process of centrifugal filtration is completed. Briefly, solid and liquid are separated under the centrifugal force, just like a washing machine.

Product Components

Machine Body

The machine body is composed of a liner, a casing, a chassis and a vibration system. The casing and the chassis are connected by a screw hole of the chassis and a sealing band of a lower portion of the casing through the pressure plate. The whole body is supported by four buffer angles. The main function of the chassis is to collect and drain the filtrate.

It is the main part of the machine and consists of a porous drum body, a drum bottom, a bottom hoop, and a liquid intercepting plate and other components.

Gearing

The spindle device is composed of a spindle, a bearing, a bearing housing and other components. The top of the spindle has a thread for screwing the drum so that the drum can be pressed with a nut. The spindle is equipped with two bearings and is supported by the bearing housing. The bearing housing is fixed in the middle of the chassis. The lower end of the spindle is equipped with a pulley.

The gearing is mainly composed of pulleys and other components. When the motor is running, the pulley is driven by the motor wheel to drive the drum for high-speed separation.

Product Prameters

| Model | Drum Diameter mm | Drum Height mm | Volume L | Rotating Speed r/min | Motor Power KW | Size mm | Weight KG |

| PP-15 | 300 | 250 | 15 | 2000 | 1.1 | 950*500*480 | 210 |

| PP-25 | 300 | 350 | 25 | 2000 | 1.5 | 950*500*580 | 220 |

| PP-45 | 450 | 300 | 45 | 1500 | 2.2 | 1250*700*760 | 450 |

| PP-60 | 450 | 400 | 60 | 1500 | 3 | 1250*700*860 | 470 |

| PP-85 | 600 | 300 | 85 | 1250 | 3 | 1500*900*950 | 970 |

| PP-110 | 600 | 400 | 110 | 1250 | 4 | 1500*900*1050 | 1000 |

| PP-140 | 600 | 500 | 140 | 1250 | 5.5 | 1500*900*1150 | 1030 |

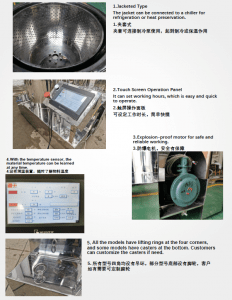

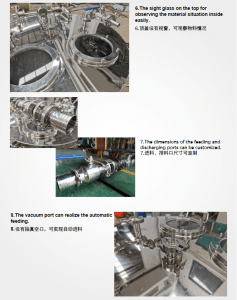

Product Details

[/ux_text]

Pre-Sale Service

- Provide 24-hour technical consultation and reply;

- Provide professional quotation information;

- Provide detailed product performance specification;

- According to product’s using condition, technicians will offer rationalization proposals to assist clients to select proper product types;

- Provide other corollary equipment according to client requirements.

In-Sale Service

- With supervision from the source of products, the qualified rate of raw materials entering the factory can reach 100%;

- Whole manufacturing process are in strict accordance with promised procedure requirements, product qualified rate can reach100%;

- Provide product’s inspection record of key junctures to customers;

- Provide production schedule photos to customers at regular intervals;

- Package and transport of products are in strictaccordance with the export standard;

- Provide transportation schedule information to clients timely.

After-Sale Service

- Provide targeted installation video;

- Under the premise of correct installation, normal maintenance and using, we guarantee one-year warranty period;

- When warranty period has expired, our sold products enjoys lifetime guarantee repair, we only charge cost price for changing product’s standard component and sealing component;

- During installation and adjustment period, our after-sale service staff will communicate with customers frequently to know product’s running state in time. Assist customers to install and adjust products until customers are satisfied;

- If product has malfunction during operation period, we’ll offer you satisfied answer in time. We’ll reply you within 1 hour and provide solution or send staff to spot within 24 hours after receiving maintenance notification;

- Lifelong free technical support. Conduct satisfaction survey and inquiry equipment running condition to clients by telephone or e-mail semiannually from the first day of equipment running, put on records of acquired information;

- Provide assistance in solving problems such as equipment damage in the transport.