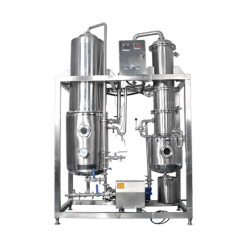

A vacuum evaporator refers to a device that can do evaporation under vacuum condition. It is a natural circulation type with external heating. The vacuum evaporation is a physical process. The evaporation rate of the solvent in the solution is related with external resistance. With the boiling point of the solution decreasing under vacuum condition, the resistance of the solvent molecules to escape from the liquid surface decreases. Meanwhile, the negative pressure in the internal space of the evaporator is caused by a vacuum pump or a water jet pump. The difference between the internal pressure and the bottom pressure can drive the solution to circulate automatically, thus increasing the evaporation rate.

Why Vacuum is Used in the Evaporator?

As we mentioned above, the boiling point of the liquid material can be lowered by using vacuum in the evaporator. Thus the need for heat during the boiling and the condensation can be reduced or eliminated. Furthermore, it has other technical advantages. For example, it can distillate other liquid with high boiling point, while avoid decomposing temperature-sensitive substances.

Applications of a Rotary Vacuum Evaporator

A rotary evaporator is mainly used for the process of evaporation, concentration, crystallization, drying, separation, and solvent recovery, and especially used for the continuous distillation of large amounts of volatile solvents under reduced pressure. With so many application purposes, there is no doubt that a rotary evaporator can be applied in many areas. For example, it can be used in the small and pilot experiments and production in the biological, pharmaceutical, chemical fields and even food-making industries.

Advantages of a Vacuum Evaporator

- The vacuum evaporated film is highly pure and has an extremely high quality and it is also more precise in controlling the thickness of the film. Compared to other evaporation, vacuum evaporation can be controlled electronically to allow the flask to operate under suitable conditions to further increase its evaporation area.

- The growth mechanism of the film is relatively simple. The main categories of films include electron evaporation plating, electron beam evaporation plating, high frequency induction heating political plating, heating evaporation plating, and so on.

- The structure of the vacuum evaporation equipment is simple and easy to operate. Simple equipment greatly reduces its cost and makes it more competitive in the evaporation process. Its convenient operation makes it more suitable for customers’ needs.

- The film is highly efficient to form, and has a clean pattern. Due to the high production efficiency of the film, the formation time of the film is also greatly shortened.

The above are all advantages of a vacuum evaporator. The vacuum evaporated film has a high purity, simple growth mechanism, simple structure and higher film efficiency. Vacuum is an effective means of evaporation, which can greatly reduce material resources.

As an effective form, vacuum evaporation is an ideal way. If you want to know more about vacuum evaporation, please contact Lanphan. Lanphan enjoys a good reputation in the domestic and foreign markets, and has been focusing on the development of experimental instruments and pipe fittings for many years. We are happy to provide you with more help. For more information, please contact rotovap@lanphan.com.

Related Products:

Related Posts:

https://www.rotovap.cn/rotary-evaporator/6335.html

https://www.rotovap.cn/rotary-evaporator/6323.html

https://www.rotovap.cn/falling-film-evaporator-problems/3647.html