As a common device in laboratory, a vacuum pump is used to create or maintain the required vacuum level. It generally has a greatly wide application areas as a accessory equipment for other laboratory devices. For example, it can be used in the laboratory, an engineering or processing area, and even the process of moving liquids from one location to another.

What is a Vacuum Pump?

A vacuum pump refers to a device or equipment that uses mechanical, physical, chemical or physical-chemical methods to evacuate the pumped container to obtain a vacuum. A vacuum pump is a device that uses various methods to improve, generate, and maintain a vacuum in a sealed space. It can be used in pharmaceutical and chemical industries, vacuum coating, vacuum drying, surface treatment, vacuum smelting, brick, ceramic manufacturing, food packaging, milking, beverage industry and so on. The role of the vacuum pump is to remove gas molecules from the vacuum chamber, reduce the gas pressure in the vacuum chamber, and help to reach the required vacuum degree.

How does a Vacuum Pump Work?

All vacuum pumps work in the same manner essentially. By making use of the pressure difference between two spaces, the majority of gas molecules or liquids are moved from one area to another area so that the former can obtain a lower pressure or vacuum condition. Nowadays, there are three kinds of working principles of vacuum pumps, including mechanical, physical and chemical ways. It is often required that more than two vacuum pumps should cooperate with each other in order to reach certain vacuum pumps.

Three common types of vacuum pumps’ working principles are concluded in detail as follows:

1. Water Circulating Vacuum Pump

The water circulating vacuum pump takes advantage of volume change of the cavity to realize suction and exhaust. Specifically speaking, an appropriate amount of water is put into the pump as the working liquid, which will be thrown around by rotating impellers. Because of centrifugal force, the water forms a closed ring of approximately equal thickness depending on the shape of the pump chamber. The inner surface of the lower part of the water ring is just tangent to the hub of the impeller, while the inner surface of the upper part of the water ring is just tangent to the tip. (Actually, the blades have a certain insertion depth in the water ring.) At this time, a crescent space is formed between the impeller hub and the water ring, which is divided into several small cavities equal to the number of blades by the impeller.

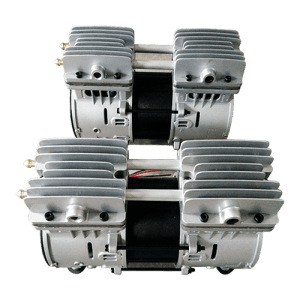

2. Diaphragm Vacuum Pump

When a diaphragm vacuum pump is working, the crank connecting rod mechanism drives the plunger to do reciprocating movement under the action of the motor. The movement of the plunger passes to the diaphragm through the working liquid(generally oil) in the cylinder so that the diaphragm agitate back and forth.There is a diaphragm in the head part of the cylinder that can separate the transported liquid from the working liquid. When the diaphragm moves to one side of the transmission mechanism, the working chamber in the pump cylinder is negative pressure and thus the liquid is inhaled; when the diaphragm moves to another side, the liquid is discharged. The transported liquid is separated from the working liquid by the diaphragm in the pump cylinder, and only contacts with the pump cylinder, suction valve, discharge valve and inner side of the diaphragm without contacting the plunger and the sealing device. It makes important parts like the plunger can completely work in the oil medium and be in a good working state.

3. Rotary Vane Vacuum Pump

The rotary vane vacuum pump is one of the basic equipment for removing gas from sealed containers. A rotor is arranged in the pump chamber, and a rotary vane is arranged in the rotor slot. When the rotor drives the rotary vane to rotate, the rotary vane is closely attached to the chamber wall, and the inlet and exhaust ports are separated. The volume of the intake manifold is periodically expanded to inhale, and the volume of the exhaust chamber is periodically reduced to compress the gas. The exhaust valve is exhausted to obtain a vacuum. Its working performance consists of two parts: high pressure stage and low pressure stage. Its suction port is connected with vacuum equipment. When operating, the gas in the container is inhaled and discharged in large quantities. When the equipment is vacuumed, the high pressure stage exhaust valve is closed and the high pressure is closed. The gas at the stage inlet will be transferred to the second stage, and a certain vacuum can be obtained by inhaling and discharging the vacuum device through the second stage.

[title text=”Related Products” tag_name=”h2″ color=”rgba(32, 163, 219, 0.81)”]

[ux_products ids=”13920,216,205,203″]

[title text=”Related Posts” tag_name=”h2″ color=”rgba(32, 163, 219, 0.81)”]

https://www.rotovap.cn/vacuum-pump/6498.html

https://www.rotovap.cn/vacuum-pump/1794.html

https://www.rotovap.cn/vacuum-pump/1456.html