As a kind of mechanical device, the rotary tablet press mainly rotates to compress powder or granules into tablets of uniform size, shape and weight. With simple, stable, accurate and safe operation, it greatly increases the output of tablets in pharmaceutical field and other industries.

Components of Rotary Tablet Press (Multi-Station Tablet Press)

1. Turret structure: it is regarded as the primary working part, mainly composed of the upper and lower bearings, main shaft, turret and other components. The dies are evenly distributed on the turret. The flat key is used to transfer torque between the turret and the main shaft. The main shaft, supported on the bearing, driven by side-worm gear and connected by the spline, is rotated to make the turret rotate.

2. Ram mechanism: the ram mechanism has the cylindrical ram and plane concave wheel composed of the upper and low rails. They are serves as the tracks where upper and lower punches move.

3. Filling regulation device: it is mainly used to adjust tablets’ weight. The filling regulation device is installed inside the main body. The moon-shaped filling rail can be observed on the plane of the main body, which can moves up and down under the action of helix to control the filling capacity.

4. Pressure (thickness of tablets) regulation device: the pressure (thickness of tablets) can be adjusted by regulating the lower pressure roller. The lower pressure roller is installed inside the main body, sleeved on the eccentric shaft and connected to the hand wheel. When adjusting the hand wheel, the lower pressure roller is driven by the eccentric shaft to move up and down to regulate pressure, so that the thickness and hardness of tablets can be controlled. The upper pressure roller can also function as the regulation device, but generally it isn’t regulated.

5. Feeding device: it is composed of the hopper, regulating screws, feeder and other components. The height of hopper and the gap between the feeder and the turret should be adjusted according to the fluidity of granules.

6. Transmission device: it consists of the motor, synchronous pulley, worm gear reducer, handwheel and other parts. The motor is installed on the baseboard. After starting up the motor, it can transfer the momentum to the speed reducing worm amplitude by a pair of synchronous belts.

The normal operation of a rotary tablet press is closely related to the mutual cooperation of each component. Not a single one of these parts can be dispensed with.

Diaphragm Vacuum Pump VS. Rotary Vane Vacuum Pump

Vacuum pumps are widely applied in many industries with the deep development of modern science and technology. They can be used for scientific research, production

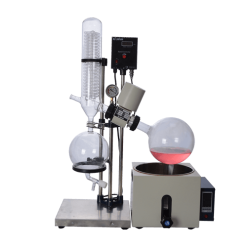

How Can We Use Rotary Evaporator for Extraction?

[ux_image id=”24452″ lightbox=”true” caption=”true” image_hover=”zoom” image_hover_alt=”zoom-fade” animate=”bounceInUp”] [gap] What is Rotary Evaporation? Rotary evaporation means that the evaporation is completed by rotary process. Under the

What is the Primary Advantage of a Rotary Evaporator over Distillation?

Rotary evaporators are common laboratory equipment mainly composed of a motor, a rotating flask, a water or oil bath and a condenser tube and other

What are Applications of a Rotary Evaporator?

What is a Rotary Evaporator? A rotary evaporator is an indispensable equipment for the processes of evaporation, concentration, crystallization, drying, separation, and solvent recovery in

How to Use a Rotary Evaporator?

A rotary evaporator (rotovap or rotavap) refers to a kind of equipment for solvent evaporation under reduced pressure, which is composed of a vacuum system, a

Advantages and Disadvantages of a Rotary Evaporator

What does a Rotary Evaporator do? A rotary evaporator (rotovap or rotavap) refers to a kind of equipment for solvent evaporation under reduced pressure, which