What is a Closed Loop Extractor?

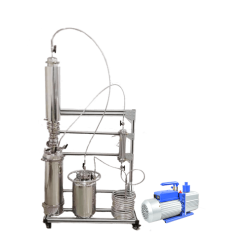

A closed loop extractor is a device used to extract solvents from solid substance. It’s a loop system. It is widely used for cannabis concentration in industry. In the whole process, there are several parts serving the extraction of solvents. Solvents can be used and recycled in the closed loop extractor, which is very economic for users and very environmentally friendly for people.

Functions of Butane in a Closed Loop Extractor

When a closed loop extractor works, the material should be put in the material column to get soaked by a certain solvent, such as butane and ethanol. In this process, substances get extracted. Then the mixture will be transferred into next column, while the extracted substances will be saved in the bottom container for people to obtain. The solvent can be recycled and used for several times. In conclusion, the butane functions as the solvent to extract substances. The butane extraction usually occur in a closed loop extraction system.

Benefits of Butane Extraction

With a low boiling point, the butane can be rapidly distilled from the extract, and the product can be degraded without using high temperature. The butane can be used for full plant extracts and the post-processing can produce different consistencies. As a result, the butane extraction is usually regarded as a better method.

How to Fill a Butane Recovery Tank?

A butane recovery tank should be filled under certain conditions. What should be done is to pull down the recovery tank to -29.5Hg, chill it and connect the can tapper to the low side of refrigerant pump. It is greatly essential to fill a butane recovery tank properly under right circumstances due to mistaken conditions will lead to a low-efficiency process.

How to Recover Butane?

As we mentioned above, the butane can be recycled and reused for several times. So how to recover butane in a closed loop extraction system? A closed-loop extractor mainly consists of three parts: a solvent tank, a material column and a receiving foundation. During its operation, the solvent tank is generally used to store and recycle butane and other solvents. Equipped with a safety valve, it adopts the design of the gas-liquid double valves as well as the auxiliary design of a discharge interface for non-condensable gas. A vacuum pump is involved in the butane recovery as well. It can be used to pull the initial vacuum in the system so that the solvent can move through easily. And the solvent tank can be evacuated to recover butane.

Butane Extraction Tips

Firstly, the butane should be stored in a cool, ventilated warehouse. The warehouse temperature should not exceed 30℃. And keep away from fire and heat.

Secondly, avoid exposing to direct sunlight. It should be stored separately from oxygen, compressed air, oxidant, etc.

Thirdly, the lighting, ventilation and other facilities during storage should be explosion-proof, and the switch should be set outside the warehouse.

[title text=”Related Products” tag_name=”h2″ color=”rgba(32, 163, 219, 0.81)”]

[title text=”Related Posts” tag_name=”h2″ color=”rgba(32, 163, 219, 0.81)”]

https://www.rotovap.cn/blog/4074.html

https://www.rotovap.cn/blog/3868.html

https://www.rotovap.cn/blog/6571.html