A rotary evaporator is usually considered as an efficient separation equipment that removes substances from sample materials by getting substances evaporated out of mixtures. In the rotary evaporator equipment, the heating mantle plays an essential role, which is to evaporate different substances by being set at different substances’ boiling points. A rotary evaporator is used to concentrate and separate substances in industrial field, chemical labs, food-making field, textile field and other fields. During the working process, the evaporation flask keeps rotating at a constant speed, in order to increase the evaporation speed by enlarging the evaporation area.

Definitions of Rotary Evaporator

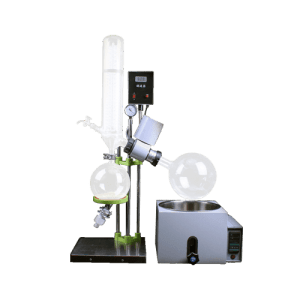

A rotary evaporator (rotovap or rotavap) refers to a kind of equipment for solvent evaporation under reduced pressure, which is composed of a vacuum system, a heated water or oil bath, a condenser and a motor that rotates the evaporation flask. As its name suggests, what is special is that the evaporation flask can rotate.

Parts of a Rotary Evaporator and Their Functions

A complete rotary evaporator is generally composed of the following parts, which cooperate with each other and all play an essential role in the working process of a rotary evaporator.

- Evaporation Flask: The sample can be evaporated at the evaporation flask.

- Rotary Motor: The rotary motor is used to drive the evaporation flask rotating at a continuous and constant speed in order to obtain a larger evaporation area and higher evaporation efficiency.

- Vacuum System: The vacuum system can be used to reduce the pressure within the rotary evaporation system so that the solvent will have a lower boiling point at a reduced pressure.

- Heating Bath: The heating bath is usually a hot water bath, which can be used to heat sample in the evaporation flask and regulate temperature.

- Condensate Pipe: There are double spiral serpentine condenser coils, vertical condensing glass assembly and other types of condensate pipes, which are used to condense the evaporated sample.

- Evaporation Pipe: The evaporation pipe has two functions. One is to protect the sample during its rotation, and the other is to enable the vacuum system to suck out samples.

- Receiving Flask: The receiving flask can recycle the sample after it’s being condensed.

- Chiller: It is a device used to cool equipment.

How does a Rotary Evaporator Work?

A rotavap evaporates solvents from samples by utilizing the principle that the solvent will have a lower boiling point at a reduced pressure. Specifically speaking, the stepless speed regulation is adopted to make the evaporation flask rotate at a constant speed. By the rotation, materials can form a large area of uniform thin film on the inner wall of the flask. The evaporation flask is heated evenly by a water or oil bath, and materials, with a lower boiling point, is evaporated rapidly under the vacuum condition. The solvent steam is recycled in the receiving flask after being cooled by the high efficiency glass condenser.

Operating Procedures of a Rotary Evaporator

The working process of rotary evaporator is a consecutive process under a reduced environment. There are several steps for the operation:

a. Under reduced pressure, the evaporation flask was continuously rotated while the solvent was being distilled. The evaporation flask is a pear-shaped or round-bottomed flask with a standard ground mouth connection. It is connected with the pressure reduction pump through a coil condenser.

b. After substances get evaporated by heating, the gas-phase substances will go into the condensing part to get condensed. In this step, gas substances are transferred through the glass tubes.

c. After gas-phase substances got condensed into liquid-phase, the liquid-phase substances will be transferred into the receiving flask, which is the final destination of extracted substances. And then users will take down the receiving flask from the rotary evaporator equipment.

During the whole working process, there is always a vacuum pump providing a vacuum environment for the rotary evaporator, which guarantees the whole system work in a reduced environment and the automatic feeding system formed by the pressure difference between atmosphere pressure and vacuum pressure.

Advantages of a Rotary Evaporator

1. Higher evaporation efficiency.

There are several factors contributing to higher evaporation efficiency.

Firstly, the rotating flask can rotate at a constant speed, and materials can form a widespread film on the inner surface of the flask, which improves the evaporation efficiency greatly. Secondly, the high-efficiency glass condenser can improve the evaporation efficiency as well. Last but not least, continuous feeding and high vacuum degree are another factors.

2. Better security.

The stainless steel and aluminum alloy are widely used in the mechanical structure, and all glass parts are made of heat-resistant high borosilicate glass, which ensure a better security. Besides, the water/oil bath can be equipped with transparent covers to prevent splashing, and anti-explosion frequency changer and dynamo are available as well. All of these designs contribute to better security.

3. More convenient operation.

It’s much more convenient to use a rotary evaporator, because of the electrodeless speed regulation, digital display K Type Sensor and intelligent temperature control and other designs adopted by it.

Tips on Using a Rotary Evaporator

- In the beginning, remove gas from the sealed equipment to get a partial vacuum before rotating the evaporation flask, which can prevent the evaporation flask from falling down.

- In the end, stop the rotation before stopping vacuum pump to prevent evaporation flask falling down or suck-back.

- Make sure there is water or oil when the thermostatic water or oil bath is working.

How to Install a Rotary Evaporator?

How to Use a Rotary Evaporator for Distillation?

[title text=”Related Products” tag_name=”h2″ color=”rgba(32, 163, 219, 0.81)”]

[ux_products style=”normal” width=”full-width” columns=”3″ ids=”2084,849,128,2155,70,49″]

[title text=”Related Posts” tag_name=”h2″ color=”rgba(32, 163, 219, 0.81)”]

https://www.rotovap.cn/rotary-evaporator/6340.html

https://www.rotovap.cn/rotary-evaporator/6332.html

https://www.rotovap.cn/rotary-evaporator/6326.html