Description

Product Introduction

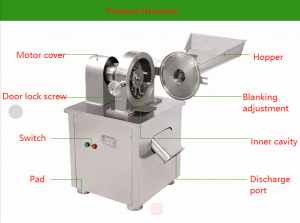

The pharmaceutical pulverizer utilizes the high-speed relative movement between the movable toothed disk and the fixed toothed disk to crush the pulverized object by the combined effects of tooth impact, friction, and material impact. This machine is simple and firm in structure, stable in operation, good in crushing effect, and the crushed material is directly discharged from the pulverizing room. The particle size can be achieved by selecting screens with different apertures.

The inside of the casing is machined to a smooth surface, which has changed the previous phenomenon of rough and powder accumulation on the inner wall of the machine, so that the production of medicines, foods, and chemicals can better meet national standards.

Working Principle

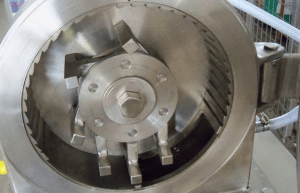

The pulverizer adopts the impact crushing method, using the internal six high speed movement of the movable hammer body and the relative movement of the fixed gear ring around, so that the material by hammer teeth collision, friction, impact each other and get crushed.The crushed material is screened through the sieve through rotating centrifugal force and then enters the capture bag.

Structural Features

The powder collection chamber of this machine adopts a fully enclosed sound-absorbing structure, which can effectively reduce the working noise. This machine is made of SS321 stainless steel material, which has strong wear-resistant and corrosion-resistant characteristics, and is suitable for processing advanced and corrosive materials. This machine adopts the impact crushing method, after the material enters the pulverizing room, it is impacted by six movable hammers rotating at a high speed, and crushed after the ring gear and the material collide with each other. With the help of the airflow, the crushed material enters the powder bag through the sieve, leaving no residue.

This machine has the advantages of high efficiency, low noise, reliable working performance and product quality, safe operation, sanitation and low consumption.

Product Application

This machine is suitable for the crushing of various types and small batches of Chinese herbal medicines, precious medicinal materials, ores and chemical raw materials in medicine, agriculture, food, chemical, alloy, metallurgy, geology, scientific research, etc. It is especially suitable for crushing dry brittle materials.

Product Classification

Pulverizers are generally divided into four categories: machine mills, pneumatic crackers, grinding machines, and low-temperature mills.

Product Parameters

| Model | Processing capacity(kg/h) | Rotating speed(r/min) | Feeding size(mm) | Crushing particle size (mesh) |

Power (kw) |

Price | Package dimensions(mm) | Weight(kg) |

| LF-20B | 60-150 | 4500 | 6 | 60-120 | 4 | 1.3 | 550x650x1200 | 150 |

| LF-30B | 100-300 | 3800 | 10 | 60-120 | 5.5 | 1.65 | 600x750x1350 | 210 |

| LF-40B | 160-800 | 3400 | 12 | 60-120 | 11 | 2.8 | 700x850x1550 | 350 |

| LF-50B | 300-1000 | 2900 | 15 | 60-120 | 15 | 3.6 | 800x870x1780 | 500 |

| LF-60B | 500-1500 | 2900 | 15 | 60-120 | 22 | 5 | 900x900x1910 | 760 |

| LF-80B | 600-2000 | 2000 | 15 | 60-120 | 30 | 7.8 | 1000x950x2100 | 1000 |

Remarks: The quotation does not include tax, and includes packaging and shipping.

Product Details

1.Fixed toothed disc: fix on the door with a large fixed toothed disc.

2.Movable toothed disc: there are beating teeth, main crushing teeth and crushing teeth.

3.All processed surfaces are smooth and clean, and there is no dust accumulation.

Precautions

- Before use, check whether all fasteners of the machine are tightened and whether the belt is tensioned.

- The rotation direction of the spindle must be in accordance with the direction of the arrow shown on the protective cover, otherwise it will damage the machine and may cause personal injury.

- Check whether the electrical appliances are complete.

- Check whether there are any hard objects such as metal in the pulverizing room of the machine, otherwise the cutters will be damaged and the operation of the machine will be affected.

- The purity of the materials must be checked before crushing, and no hard metal impurities are allowed to be mixed in, so as to avoidbreaking the cutteror causing burning and other accidents.

- The oil cup on the machine should be filled with lubricating oil frequently to ensure the normal operation of the machine.

- Stop feeding before stopping the machine. If you do not continue to use it, remove the leftovers in the machine.

- Regularly check whether the cutter and the sieveare damaged. If damaged, it should be replaced immediately.

- The machine body will vibrate slightly when in use. Be sure to tighten the cover connection handle to avoid accidents.

Common Faults and Solutions

|

Faults |

Causes |

Solutions (The power must be cut off to perform the following operations) |

| The motor does not rotate after the power is turned on | 1. Poor power contact or loose plug

2. Poor contact of the power switch 3. Poor contact of the micro switch 4. The thermal protector fails |

1. repair the power supply or replace the joint

2. repair or replace the switch 3. Adjust the micro switch 4. Replace the thermal protector |

| After energizing, the motor rotates too slowly or does not rotate and vibrates | 1. The mechanical part is stuck

(there is foreign matter in the pulverizer slot) 2. The centrifuge is not turned on 3. The power supply voltage is too low |

1. Remove the foreign matter in the pulverizer slot, start the machine and run it idling for half a minute before feeding slowly

2. Adjust the power supply voltage |

| The surface of the motor housing is overheated | 1. Excessive load

2. The motor is humid 3. The power supply voltage is too low |

1. Reduce the working pressure

2. Dry the motor 3. Adjust the power supply voltage |

| Ring fire or large sparks on the surface of the commutator | The surface of the commutator is not smooth | Remove debris on the surface of the commutator |

Reviews

There are no reviews yet.