A glass reactor can play a role as a reaction material in laboratory instruments and is often used by modern fine chemicals, biopharmaceuticals, scientific research experiments and other industries. There are various types of glass reactors, which can be divided into the two-layer glass reactor, the single-layer glass reactor, and the high-pressure reactor. And these reactors have the functions of explosion-proof and non-explosion-proof. In fact, from the practical use of the situation, the use of the explosion-proof glass reactor is very few. Unless the material safety requirements of the reaction are high, an explosion-proof glass reactor must be used. Generally we choose these ordinary single or double glass reactors.

Tips on Using Glass Reactors

1. No load is not suitable for high speed operation;

2. Keep the speed controller and motor dry. Because the service life of the electrical box is greatly affected by the surrounding humidity and temperature;

3. The ground wire must be well grounded, and the high temperature bath must be connected to the air switch;

4. Electric shock may still occur within 5 minutes after power supply is cut off due to frequency converter or capacitor discharge;

5. Please avoid the watch, ring and other hard objects when operating the instrument on the glass damage;

6. When the glass reactor needs to be heated, it should be gradually heated. Especially when heating at a high temperature, it is generally recommended to use a heat-conducting oil that is less harmful to the human body.

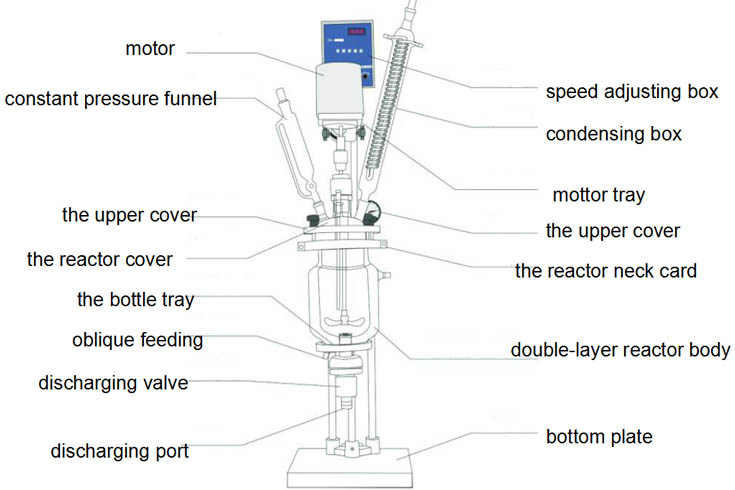

Glass reactor structure diagram:

Next, we will introduce the latest glass reactors:

Introduction of S212-50L Double Layer Glass Reactor

Lanphan S212-50L double-layer glass reactor’s reaction flask volume is 50L, interlayer volume is 12L, stirring diameter of axle is 12mm, power of stirring is 120W. S212-50L double-layer glass reactor is an audacious product who has combined advantages of domestic and foreign like products, it adopts double-layer glass design, put reaction solvent in internal layer to do stirring reaction, connect different cold and heat sources (refrigerating fluid, hot water or hot oil) to interlayer to do cyclic heating or cooling reaction. Under set constant temperature condition, you can conduct stirring reaction under normal or negative pressure in airtight glass reactor, as well as conducting backflow and distillation of reaction solution. S212-50L double-layer glass reactor is an ideal pilot test and production equipment for modern fine chemical engineering, biological pharmacy and new material synthesis. This glass reactor series mainly contains following parts: double-layer glass reaction kettle, a set of component cover of glass reactor, condenser, constant voltage funnel, frequency conversion controller, rotate stirring and sealing system, stainless steel frame system, etc.

Product advantages

1.Constant speed, no brush, no spark, safe and stable, can work continuously.

2.The complete glass instrument is produced with G3.3 borosilicate glass and has good chemical and physical properties.

3.The PTFE assembly is sealed to maintain a high degree of vacuum.

Matching products

SHZ-95B Vertical Circulating Water Vacuum Pump has the following characteristics:

(1)This machine adopts five taps and can be used separately or in parallel. It is equipped with a vacuum gauge.

(2)No pollution, corrosion resistance, low noise, convenient and durable, water and electricity saving.

(3)The main machine is made of stainless steel movement and anti-corrosion material movement.

(4)Small size, light weight, easy to move, beautiful appearance.

(5)Water level of the machine, indicator light display:High, medium, low.

DLSB series cooling liquid circulating pump

DLSB-50 Low Temperature Cooling Liquid Circulating Pump has the following characteristics:

1. Imported air-cooled fully enclosed compressor unit with advanced performance and reliable quality.

2. Refrigeration unit special relays, protectors, capacitors, refrigeration components, imported high-quality components.

3. Digital display constant temperature display, microcomputer temperature control, simple operation, eye-catching.

4. Large refrigerating capacity and fast refrigerating speed greatly improve working efficiency

Introduction of S212-20L Double-layer Glass Reactor

S212-20L double-layer glass reactor’s reaction flask volume is 20L, interlayer volume is 8L, stirring diameter of axle is 12mm, power of stirring is 90W. S212-20L double-layer glass reactor is an audacious product who has combined advantages of domestic and foreign like products, it adopts double-layer glass design, put reaction solvent in internal layer to do stirring reaction, connect different cold and heat sources(refrigerating fluid, hot water or hot oil) to interlayer to do cyclic heating or cooling reaction. Under set constant temperature condition, you can conduct stirring reaction under normal or negative pressure in airtight glass reactor, as well as conducting backflow and distillation of reaction solution. S212-20L double-layer glass reactor is an ideal pilot test and production equipment for modern fine chemical engineering, biological pharmacy and new material synthesis. This glass reactor series mainly contains following parts: double-layer glass reaction kettle, a set of component cover of glass reactor, condenser, constant voltage funnel, frequency conversion controller, rotate stirring and sealing system, stainless steel frame system, etc.

Product advantages

1.Constant speed, no brush, no spark, safe and stable, can work continuously.

2.The complete glass instrument is produced with G3.3 borosilicate glass and has good chemical and physical properties.

3.The PTFE assembly is sealed to maintain a high degree of vacuum.

Matching Products

SHZ-95B Vertical Circulating Water Vacuum Pump has the following characteristics:

(1)This machine adopts five taps and can be used separately or in parallel. It is equipped with a vacuum gauge.

(2)No pollution, corrosion resistance, low noise, convenient and durable, water and electricity saving.

(3)The main machine is made of stainless steel movement and anti-corrosion material movement.

(4)Small size, light weight, easy to move, beautiful appearance.

(5)Water level of the machine, indicator light display:High, medium, low.

DLSB series cooling liquid circulating pump

DLSB-50 Low Temperature Cooling Liquid Circulating Pump has the following characteristics:

1. Imported air-cooled fully enclosed compressor unit with advanced performance and reliable quality.

2. Refrigeration unit special relays, protectors, capacitors, refrigeration components, imported high-quality components.

3. Digital display constant temperature display, microcomputer temperature control, simple operation, eye-catching.

4. Large refrigerating capacity and fast refrigerating speed greatly improve working efficiency.

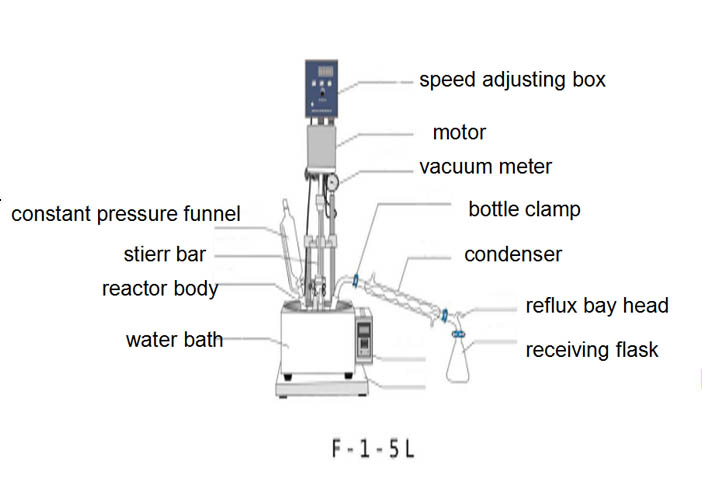

Introduction of F-10L Single Layer Glass Reactor

F-10L single layer glass reactor is a series product of single layer glass reactor, its max volume is 10L, max rotating speed can reach to 450rpm, its reaction bottle volume is 10L, that’s why it is known as F-10L single layer glass reactor, also called: glass vacuum reactor, extractor, multifunctional reactors, it can make various of solvent synthesis reaction under the condition of constant temperature. The reactor part is controllable sealed structure, which can use negative pressure continuous inhalation of various liquids and gases, and make reflux or distillation under different temperature.

Product advantages

1.Constant speed, no brush, no spark, safe and stable, can work continuously.

2.The complete glass instrument is produced with G3.3 borosilicate glass and has good chemical and physical properties.

3.The PTFE assembly is sealed to maintain a high degree of vacuum.

Matching Products

SHZ-95B Vertical Circulating Water Vacuum Pump has the following characteristics:

(1)This machine adopts five taps and can be used separately or in parallel. It is equipped with a vacuum gauge.

(2)No pollution, corrosion resistance, low noise, convenient and durable, water and electricity saving.

(3)The main machine is made of stainless steel movement and anti-corrosion material movement.

(4)Small size, light weight, easy to move, beautiful appearance.

(5)Water level of the machine, indicator light display:High, medium, low.

DLSB series cooling liquid circulating pump

DLSB-50 Low Temperature Cooling Liquid Circulating Pump has the following characteristics:

1. Imported air-cooled fully enclosed compressor unit with advanced performance and reliable quality.

2. Refrigeration unit special relays, protectors, capacitors, refrigeration components, imported high-quality components.

3. Digital display constant temperature display, microcomputer temperature control, simple operation, eye-catching.

4. Large refrigerating capacity and fast refrigerating speed greatly improve working efficiency.

Introduction of F-50L single layer glass reactor

F-50L single layer glass reactor is a series product of single layer glass reactor, its max volume is 50L, max rotating speed can reach to 450rpm, its reaction bottle volume is 50L, that’s why it is known as F-50L single layer glass reactor, also called: glass vacuum reactor, extractor, multifunctional reactors, it can make various of solvent synthesis reaction under the condition of constant temperature. The reactor part is controllable sealed structure, which can use negative pressure continuous inhalation of various liquids and gases, and make reflux or distillation under different temperature.

Product advantages

1.Constant speed, no brush, no spark, safe and stable, can work continuously.

2.The complete glass instrument is produced with G3.3 borosilicate glass and has good chemical and physical properties.

3.The PTFE assembly is sealed to maintain a high degree of vacuum.

Matching Products

SHZ-95B Vertical Circulating Water Vacuum Pump has the following characteristics:

(1)This machine adopts five taps and can be used separately or in parallel. It is equipped with a vacuum gauge.

(2)No pollution, corrosion resistance, low noise, convenient and durable, water and electricity saving.

(3)The main machine is made of stainless steel movement and anti-corrosion material movement.

(4)Small size, light weight, easy to move, beautiful appearance.

(5)Water level of the machine, indicator light display:High, medium, low.

DLSB series cooling liquid circulating pump

DLSB-50 Low Temperature Cooling Liquid Circulating Pump has the following characteristics:

1. Imported air-cooled fully enclosed compressor unit with advanced performance and reliable quality.

2. Refrigeration unit special relays, protectors, capacitors, refrigeration components, imported high-quality components.

3. Digital display constant temperature display, microcomputer temperature control, simple operation, eye-catching.

4. Large refrigerating capacity and fast refrigerating speed greatly improve working efficiency.

.

FAQ

1. Q: What is the difference between the single glass reactor and the double glass reactor?

A: The single-layer glass reactor can be directly heated and cooled, similar to the oil bath water bath, but the effect on temperature control is not ideal. There is a sandwich between the two layers of the double-layer glass reactor, and water or oil can be input through the temperature control device to form a cycle, so that the temperature control regardless of the refrigeration or heating is better and more accurate.

2.Q: What kind of environment do they apply?

A: It can be used in high temperature 200 degrees to low temperature minus 80 degrees temperature zone.

3.Q: What models are there for double-layer glass reactors?

A: Our company is the most complete glass reactor manufacturer in the market. The double-layer glass reactor includes s212-1l, s212-2l, s212-3l, s212-5l, s212-10l, s212-15l, s212-20l, s212-30l, s212-80l, s212-100l, s212-150l and s212-200l.

The single-layer glass reactor includes f-1l, f-2l, f-3l, f-5l, f-10l, f-20l, f-30l, f-50l, f-100l, f-150l and f-200l.

4.Q: What is the glass material of the glass reactor?

A: The complete glassware of the glass reactor is made of G3.3 borosilicate glass and has good chemical and physical properties.

5.Q: What is the material of the glass reactor?

A: The main material of the glass reactor is stainless steel and aluminum alloy.

6.Q: Is there an explosion-proof glass reactor?

A:There is an explosion-proof glass reactor, but the cost is more expensive than non-explosion-proof glass reactor.

[title text=”Related Products” tag_name=”h2″ color=”rgb(119, 199, 239)”]

[ux_products ids=”179,183,181,24174,23999,10220″]

[title text=”Related Posts” tag_name=”h2″ color=”rgb(119, 199, 239)”]

[blog_posts style=”vertical” columns=”3″ columns__md=”1″ depth=”2″ slider_nav_style=”simple” slider_nav_position=”outside” ids=”1038,897,1402″ image_height=”89%” image_width=”43″]