Description

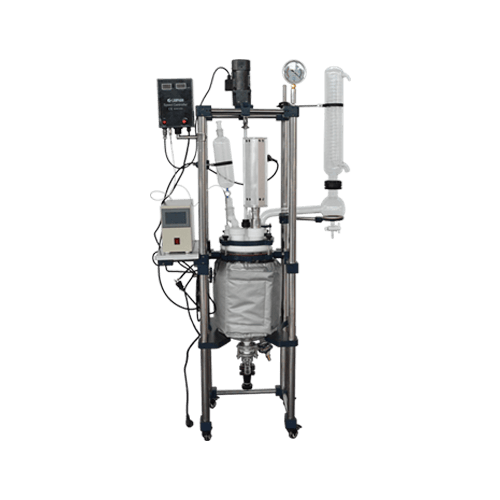

The SL212 series ultrasonic double layer glass reactor adopts double-layer glass design. The reaction solvent can be put in the internal layer to do the stirring reaction, and different cold and heat sources (refrigerating fluid, hot water or oil) can be connected to the interlayer to do the circulating heating or cooling reaction. And the ultrasonic device is equipped, which can save solvent, speed up the reaction process, enhance both the extraction rate and the dissolution rate. At a constant temperature, the stirring reaction can be done under normal or negative pressure, as well as the backflow and distillation of the reaction solution. It is an ideal pilot-plant and production equipment for modern fine chemical industry, biopharmaceutical and new material synthesis.

Product Application

An ultrasonic double layer glass reactor is an ideal equipment for lab-scale and pilot tests, biopharmaceutical, new drug research and development and new material synthesis. It is primarily used in small chemical industry, petroleum, metallurgy, coal, electronics, building materials, light industry and other fields, or the medium and small scale production.

Product Advantages

An ultrasonic double layer glass reactor is independently researched and designed, while it imports international advanced technology. It can improve the dissolution rate and speed up the reaction process, and efficiently reduce reaction failure caused by uneven dispersing of reactants concentration. Furthermore, it serves as a green, safe and simple descaling method, which is capable of effectively removing obstinate residues inside the kettle wall.

Product Parameters

| Basic Parameters | Model | S212-10L |

| Glass Material | GG-17 | |

| Frame Material | Stainless steel | |

| Pipe Fitting Material | SS 304 | |

| Moving Mode | Universal casters with braking | |

| Volume of Reaction Flask | 10L | |

| Interlayer Volume | 6L | |

| Flange Type Oil Inlet and Outlet | Low in and high out | |

| Flask Necks of Kettle Cover | PTFE seven ports | |

| Height of Discharge Port | 450mm | |

| Reaction Temperature of Kettle Body | -80~250℃ | |

| Ultrasonic Power | 2000W | |

| Ultrasonic Frequency | 20kHz | |

| Vacuum Degree | 0.098Mpa | |

| Rotating Speed of Stirring | 0-450rpm | |

| Diameter of Stirring Shaft | 12mm | |

| Stirring Power | 90W1/3 | |

| Power/Frequency(V/Hz) | 220V/50Hz | |

| Overall Dimension(mm*mm*mm) | 520*520*2000 | |

| Package Dimension(mm*mm*mm) | 1370*590*800 0.65 square meter | |

| Package Weight(KG) | 98 | |

| Function Configuration | Speed Regulation Mode | Electronic stepless speed regulation |

| Motor Configuration | Low speed booster motor, speed ratio is 3:1 | |

| Speed Display Mode | LCD digital display | |

| Temperature Display Mode | PT100 sensor digital display | |

| Sealing Method | Mechanical seal, ¢50 flange stirring port | |

| Condenser | Vertical high efficiency double reflux condenser pipe 100*670mm | |

| Reflux (Distillation) Device | Return elbow with discharge switch, 50# ball-milling mouth | |

| Dropping Device | 1L constant pressure funnel, 40# standard port | |

| Pressure Reducing Device | 34# standard port pressure reducing valve | |

| Ultrasonic Device | ¢80 flange coupling | |

| Ultrasonic Control | Touch screen LCD digital display | |

| Temperature Measuring Tube | 24# standard port | |

| Solid Feed | ¢80 flange mouth with PTFE cover | |

| Discharge Mode | Oblique type glass discharge valve, ¢80 flange mouth | |

| Vacuum Display Mode | Vacuum Gauge | |

| Stirring Connection Mode | Universal joint connection | |

| Stirring Rod | Anchor stainless steel rod, wrapped in PTFE | |

| Optional Configuration | Main Support | Tray type |

| Receiving Device | Receiving flask | |

| Explosion Proof | Explosion-proof frequency, explosion-proof motor, EX180W, 0-1400rpm | |

| Frame Part | Plastic spraying or PTFE spraying | |

| Insulated Device | Insulated cotton | |

| Sealing Part | Ceramic bearing, mechanical sealing | |

| Condenser | The horizontal condenser can lower the overall height. | |

| All laboratory instrument in our factory is independently researched and developed, and other laboratory instrument can be customized according to the actual requirements of customers. | ||

Product Details

1. The kettle body is made of PTFE, which can avoid rupture caused by the ultrasonic vibration.

2. The kettle body is equipped with the insulated device, featuring thermal insulation.

3. The discharge valve, with the special design, can discharge concentrated liquid and minute amounts of solid.

4. The main structure adopts stainless steel and aluminium alloy, which are elegant and durable.

Precautions

1. Don’t casually move driving power and directly plug in or out power supply during the operation. In case of any abnormal sound or indication, switch off the driving power immediately and troubleshoot the failure cause to avoid equipment damage.

2. It is a normal phenomenon to have some slight cavitation on the surface of tool heads after products go through the factory test.

3. There are precision components carrying high voltage in the ultrasonic device. Don’t disassemble or assemble without permission or under no guidance of professional personnel.

4. Pay attention to the case temperature of the main engine when it is used for a long time. The forced dissipation is required when the temperature exceeds 45℃ in order to ensure the normal operation of the main engine.

5. Remove the blue plastic film before use to ensure the heat dissipation. 6. It is strictly prohibited to start for a long time without load, and the no-load start shouldn’t exceed 15 seconds.

FAQ

1. Q: What is the difference between ultrasonic double layer reactor and double layer reactor?

A: Based on a double layer reactor, an ultrasonic double layer reactor is equipped with the ultrasonic device. It can improve the dissolution rate, speed up the reaction process and effectively reduce the reaction failure caused by uneven dispersing of reactants concentration. It is capable of effectively removing obstinate residues inside the kettle wall as well.

2. Q: What is the glass material of the reactor?

A: The full set of glass instrument is made of GG-17 borosilicate glass, with excellent chemical and physical properties.

3. Q: What circumstance can it be used?

A: It is applicable between -80℃ and 200℃.

4. Q: Is it easy to clean receiving flasks?

A: When the ultrasonic wave acts on the liquid, the rupture of each bubble in the liquid will produce a powerful shock wave to clean and wash the inner and outer surface of the workpiece.

5. Q: What kind of payment terms do you accept?

A: Normally we accept TT, Paypal, Western Union, Alibaba International Alipay, and L/C. The exact term will be discussed during the deal.

6. Q: How will you delivery these goods?

A: It will depend on your quantity. Normally we will choose International Express, sea and air transportation.

7. Q: How will you pack the product?

A: The small pieces are packed in special cartons, and the large pieces are packed in non fumigation wooden cases.

Reviews

There are no reviews yet.