Description

Principle of Wiped Film Distillation

Molecular distillation is a special liquid-liquid separation technology. It is different from traditional distillation which relies on the principle of boiling point difference separation, but realizes separation by the difference in the mean free path of motion of different substances.

When the liquid mixture flows along the heating plate and is heated, the light and heavy molecules will escape from the liquid surface and enter the gas phase. Due to the different free paths of the light and heavy molecules, the molecules of different substances move at different distances after escaping from the liquid surface. If a condensing plate can be properly installed, light molecules will be condensed and discharged when they reach the condensing plate, while heavy molecules cannot reach the condensing plate and be discharged along the mixed liquid. In this way, the purpose of material separation is achieved.

The distillation process is: the material is added from the top of the evaporator, and is continuously and evenly distributed on the heating surface by the material liquid distributor on the rotor, and then the film scraper scrapes the material liquid into an extremely thin, turbulent liquid film. , and advance in a spiral downward. During this process, light molecules escaping from the heating surface are condensed into liquid on the built-in condenser after a short route and almost without collision, and flow down the condenser tube through the discharge tube located at the bottom of the evaporator Discharge; residual liquid, that is, heavy molecules, is collected in the circular channel under the heating zone, and then flows out through the discharge pipe on the side.

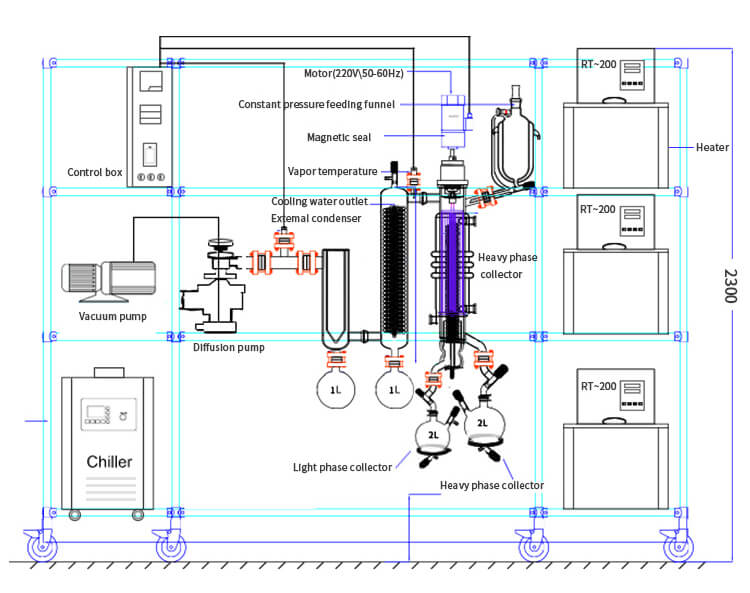

Diagram of Glass Wiped Film Distillation Kit

A complete set of wiped film distillation equipment mainly includes evaporator, vacuum pump, heater, feeding and discharging system. The core part of the wiped film distillation device is the molecular evaporator, which mainly has three types: falling film type, wiped film type and centrifugal type.

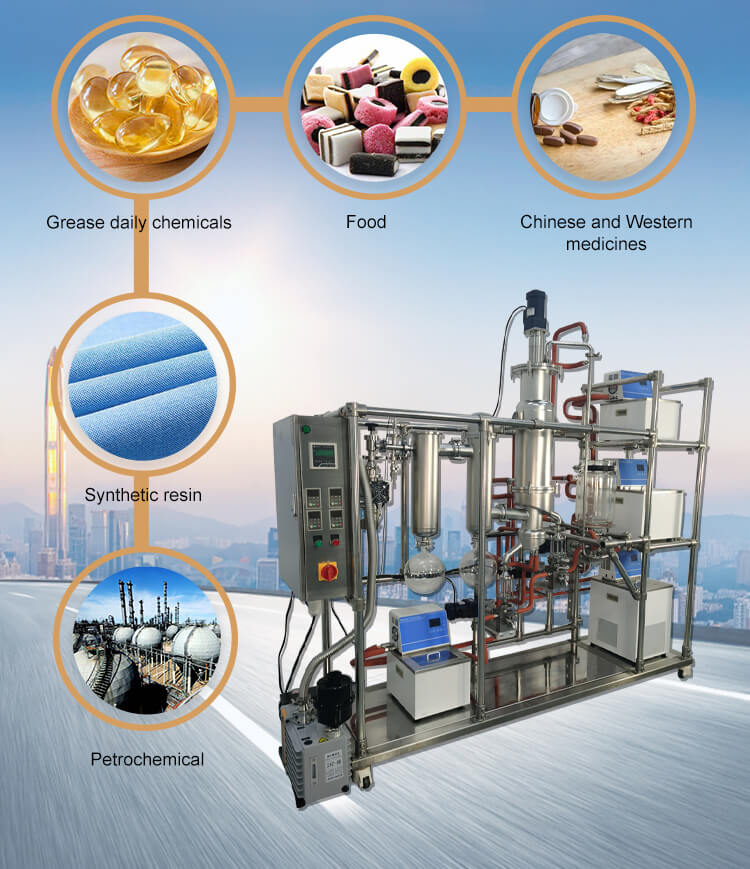

Application of Glass Wiped Film Distillation Equipment

Glass wiped film distillation is widely used in Chinese and Western medicine, food, oil, daily chemical, synthetic resin, synthetic fiber, petrochemical, pesticide biology, wastewater treatment and other industries.

Operation Instruction

- Prepare materials that meet the requirements;

- Confirm that each receiving bottle at the bottom of the device has been connected in place;

- Pour the material into the feeding barrel;

- Start the heater of the feed tank: turn on the power supply, the heat transfer oil circulation starts to run, and set the required temperature;

- Start the heater of the distiller: turn on the power supply, the heat transfer oil circulation starts to run, and set the required temperature;

- Start the thermostat with built-in condenser: turn on the power, the circulating pump starts to run, and set the required temperature;

- After each heater and thermostat have been running for a period of time and the temperature of each component is stable, connect the refrigerator.

- Start the vacuum pump system;

- The liquid material flows into the distiller at a suitable flow rate for distillation separation. The recommended speed is 100rpm∽300rpm

- Distillation is complete.

Note: The key parts of this product are made of glass.

Vacuum pump system: When opening or closing the vacuum system, it should be carried out in the order in the operation manual, otherwise the vacuum system will be damaged.

Material requirements:

Because the main body of the distillation is made of all-glass, it is fragile and difficult to disassemble, and the structure is complex and difficult to clean; therefore, after distillation and separation, it should be cleaned, such as with distilled water or ordinary organic solvent (ethanol).

Can not be cleaned with strong alkaline or strong acid cleaning solution. If the material has strong alkali or strong acid, it will reduce the service life of the equipment.

When using organic solvent for distillation, pay attention to the corrosion of the sealing ring; if it is corroded, please replace the sealing ring in time or customize the sealing ring of special material.

Parameter of Glass Wiped Film Distillation Equipment

| Model | Effective evaporation area(m2) | Inner condensation area (m2) | Outer condensation area

(m2) |

barrel inner diameter

(mm) |

Constant pressure feeding funnel volume(L) | Processing capacity

(KG/H) |

Motor Power(W) | maximum speed

(RPM) |

| FMD-60(B) | 0.05 | 0.1 | 0.2 | 60 | 1.5 | 0.1∽2.0 | 120 | 450 |

| FMD-80(B) | 0.1 | 0.15 | 0.25 | 80 | 1.5 | 0.3∽4.0 | 120 | 450 |

| FMD-100(B) | 0.15 | 0.2 | 0.3 | 100 | 1.5 | 0.5∽5.0 | 120 | 450 |

| FMD-150(B) | 0.25 | 0.4 | 0.6 | 150 | 1.5 | 1.0∽8.0 | 120 | 450 |

| FMD-200(B) | 0.35 | 0.5 | 0.6 | 190 | 1.5 | 1.5∽10.0 | 200 | 300 |

| FMD-230(B) | 0.5 | 0.65 | 0.6 | 220 | 1.5 | 2.0∽15.0 | 200 | 300 |

Our Service

Timely

Professional

Efficient

Cooperative

Certification

Packaging and Shipping

Reviews

There are no reviews yet.