Description

Product Description

The LPTPM tablet press machine is suitable for laboratory and small-scale tablet production and processing industry. It is a kind of small desktop inching continuous press machine. The machine comes with one die, and it can press different shapes and sizes of tablets by replacing the die. Both the filling depth of material and thickness of tablets can be adjusted.

Product Functions

It has the advantages of excellent performance, strong adaptability, simple operation, easy maintenance, small volume and light weight.

It can also manually press tablets without electricity. There is only one die installed on the machine, and both the filling depth of material and thickness of tablets can be regulated.

It is well suitable for pressing various traditional Chinese tablets and western tablets in pharmaceutical industry and pressing various like products in other industries, gaining popularity among consumers from all walks of life.

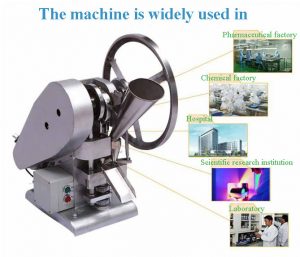

Product Application

The single punch tablet press is suitable for pressing traditional Chinese medicine tablets, western medicine tablets, chewable tablets, calcium tablets, buccal tablets, spirulina tablets, milk tablets, candy tablets, effervescent tablets, mothballs, aromatic tablets, flavor tablets, disinfection tablets, catalyst, chemical fertilizer tablets, pesticide tablets, button batteries, electronic components, metallurgical powder ceramic particles and other tablets.

It is a kind of small desktop electrical (manual) continuous pressing machine. One die is installed on the machine. Both the filling depth of material and thickness of tablets can be adjusted. Various shapes of dies can be supplied as required by customers. A single punch tablet press can press granular material into tablets, which is widely used for trial production and small scale production in pharmaceutical factory, chemical factory, hospital, scientific research institution and laboratory.

Working Principle

The working process of a tablet press covers loading, filling, main compression, molding, ejection and other procedures.

The upper and lower punches, driven by punching plate, move clockwise along the upper and lower cams respectively. When punches move to the filling section, the upper punch moves upward to bypass the feeder. At the same time, the lower punch moves downward under the action of the filling cam to exactly form a cavity with negative pressure in the die hole. The powder granules come into the cavity through the feeder. The lower punch passes through the lowest point of the filling cam to form over filling, and the upper punch gradually comes into the die hole to completely cover and press the powder in the die hole. The upper and lower punches combine with each other for molding, guaranteeing less leakage of powder and no change of filling capacity during the compression. The compression is completed when punches pass through the pressure roller. The upper punch moves up and the lower punch pushes up to bring out the pressed tablets through the ejection rail. The tablets come into the ejection device, completing a tablet pressing process.

Product Features

- It is a type of small desktop electric continuous press machine, which can also be operated manually.

- There is only one die installed on the machine, and both the filling depth of material and thickness of tablets can be regulated.

- Various sizes and shapes of tablets can be pressed by replacing different dies.

- Small volume, light weight, flexible move and simple operation.

- The turbo-charged single punch is a kind of small desktop electric continuous press machine. Compared to common single punch press machine, it is added a turbine drive without belt transmission and low noise. The tablet pressing speed can be adjusted with a frequency converter.

- It is used to press all kinds of granular materials into round tablets or other special-shaped tablets. It is an ideal device for trial production and small-scale production of scientific research institute, school, pharmaceutical factory and laboratory.

- It is an automatic continuous press machine, which can press powder and granular material into tablets used in pharmaceutical, chemical, electronic, food, laboratory and other departments.

Pressing Requirements (Customer Instructions)

There are so many kinds of powder around the world, such as herbal powder, food powder and health care powder. Not all of them are suitable for pressing tablets. General requirements for pressing tablets are as follows:

Tablets are one of the most commonly used types. The press machine can press dry granular materials or dry powder into tablets. The direct powder compression refers to directly press powder into tablets without making them into granules after sifting powder and appropriate auxiliary material respectively and mixing them.

The medicines of direct powder compression should possess good fluidity, compressibility and lubricity. But most medicines don’t possess these characteristics, which can be solved by improving the material’s properties, improving the press machine’s performance and other ways. Improve the material’s properties: when the thickness degree and crystallization morphology of medicines are unsuitable for direct compression, appropriate methods can be adopted, such as the change of particle sizes, distributions and shapes. The re-granulation and spray drying methods can be used.

Warm Prompt: If your material is never pressed into tablets, you are suggested to send the sample to us and we can do trial production for you. You can purchase products after being satisfied with trial compression effect, avoiding unnecessary troubles and losses. Welcome new and old customers to our factory for inspection and establish long term cooperation relationship.

Product Parameters

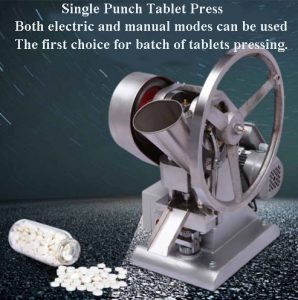

- Single Punch Tablet Press / Single Station Tablet Press

With the dual modes, both electric and manual modes can be used. It is the first choice for batch of tablets pressing.

|

Single Punch Tablet Press Machine |

||||||

| Model | TDP-1.5T | TDP-5N(TDP-1.5N) | TDP-5(T) | TDP-5S | TDP-6 | TDP-0 (3 Types) |

| Tablet Pressure / Ton | 1.5 | 5 | 5 | 5 | 6 | 1.5 |

| Diameter Range of Tablet / mm | 512 (5、6、8、10、12) |

15 | 16 | 16 | 25 | 512 (5、6、8、10、12) |

| Filling Depth / mm | - | 12 | 12 | 12 | 17 | - |

| Thickness of Tablet / mm | 2 6 | 6 | 6 | 6 | 6 | 6 |

| Production Capacity: piece / h | 5000 | 4000 | 4000-5000 | 4000-5000 | 3000 | 30-50 pieces / Minute |

| Motor Power / kw | 0.37 | 0.75 | 0.75 | 0.75 | 1.1 | |

| Rotating Speed: rpm | 1400 | |||||

| Overall Dimension / mm | 700*420*800 | 550*420*650 | 700*370*800 | 700*370*800 | 760*360*690 | 360*280*450 |

| Machine Weight / kg | 58 (include wooden cases) | 40 (50 includes wooden cases) | 120 | 125 | 190 | 20 |

| Price / RMB | 3850 (Not the main product. Less products are in stock.) | 3850 (Main product. Enough products are in stock.) | 4000 | 5280 (Main product. Enough products are in stock.) | 6930 | The paint type tablet press machine is 1500RMB. The electroplating type tablet press machine is 1900RMB. The handwheel type handwheel is 1900RMB. (Main product. Enough products are in stock.) |

| This type can change the die platen. The specification of TDP-5 or TDP-1.5 are available. | ||||||

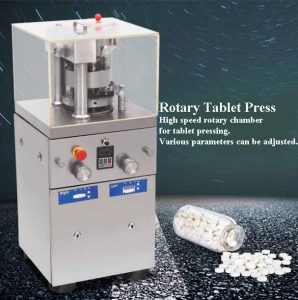

- Multi-Punch Tablet Press / Multi-Station Tablet Press

Rotary Tablet Press

High speed rotary chamber for tablet pressing.

Various parameters can be adjusted.

| Multi-Punch Tablet Press / Multi-Station Tablet Press | ||||||

| Model | ZP-5A | ZP-7A | ZP-9A | ZP-5B | ZP-7B | ZP-9B |

| Number of Stations / Pair | 5 | 7 | 9 | 5 | 7 | 9 |

| Tablet Pressure / Ton | 4 | 4 | 4 | 6 | 6 | 6 |

| Tablet Diameter / mm | 12 | 12 | 12 | 18 | 18 | 18 |

| Filing Depth / mm | 15 | 15 | 15 | 15 | 15 | 15 |

| Thickness of Tablet / mm | 6 | 6 | 6 | 6 | 6 | 6 |

| Rotating Speed / rpm | 30 | 30 | 30 | 30 | 30 | 30 |

| Production Capacity: piece / h | 9000 | 12600 | 16200 | 9000 | 12600 | 16200 |

| Motor Power / kw | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 | 2.2 |

| Overall Dimension / mm | 615*610*1200 | 615*610*1200 | 615*610*1200 | 960*660*1230 | 960*660*1230 | 960*660*1230 |

| Machine Weight / kg | 230 | 230 | 230 | 308 | 308 | 308 |

| Price / RMB | 14300 (Main product. Enough products are in stock.)

The 110V type is more expensive than it by 500RMB, and the universal wheel type is more expensive than it by 300RMB. |

15800 (Main product. Enough products are in stock.)

The 110V type is more expensive than it by 500RMB, and the universal wheel type is more expensive than it by 300RMB. |

||||

Product Details

- Various types of dies can be customized, which can be used by turns.

- Both the filling depth of material and thickness of tablets can be adjusted.

- Ejection Port

Made of stainless steel, the surface is treated by smooth processing, efficiently reducing the edge deficiency, crack, deformation and other problems during the ejection.

- Installation Position of Die

Various dies can be customized and installed for use, which is simple and convenient. Both the filling depth of material and thickness of tablets can be adjusted.

Packing and Delivery

Certification

Pre-Sale Service

- Provide 24-hour technical consultation and reply;

- Provide professional quotation information;

- Provide detailed product performance specification;

- According to product’s using condition, technicians will offer rationalization proposals to assist clients to select proper product types;

- Provide other corollary equipment according to client requirements.

In-Sale Service

- With supervision from the source of products, the qualified rate of raw materials entering the factory can reach 100%;

- Whole manufacturing process are in strict accordance with promised procedure requirements, product qualified rate can reach 100%;

- Provide product’s inspection record of key junctures to customers;

- Provide production schedule photos to customers at regular intervals;

- Package and transport of products are in strict accordance with the export standard;

- Provide transportation schedule information to clients timely.

After-Sale Service

- Provide targeted installation video;

- Under the premise of correct installation, normal maintenance and using, we guarantee one-year warranty period;

- When warranty period has expired, our sold products enjoys lifetime guarantee repair, we only charge cost price for changing product’s standard component and sealing component;

- During installation and adjustment period, our after-sale service staff will communicate with customers frequently to know product’s running state in time. Assist customers to install and adjust products until customers are satisfied;

- If product has malfunction during operation period, we’ll offer you satisfied answer in time. We’ll reply you within 1 hour and provide solution or send staff to spot within 24 hours after receiving maintenance notification;

- Lifelong free technical support. Conduct satisfaction survey and inquiry equipment running condition to clients by telephone or e-mail semiannually from the first day of equipment running, put on records of acquired information;

- Provide assistance in solving problems such as equipment damage in the transport.

[title style=”center” text=”Send Message” color=”rgba(32, 163, 219, 0.81)”]

Error: Contact form not found.

Reviews

There are no reviews yet.