Description

Product Description

Molecular distillation is a special liquid-liquid separation technology, which is different from the traditional distillation based on the separation principle of material boiling point difference, but based on the difference in the mean free path of molecular motion of each material in the mixture to achieve separation. According to the principle of the mean free path of molecular motion, as shown in the figure above, in an ideal state, let the liquid mixture flow and heat along the heating plate, and light and heavy molecules will escape from the liquid surface and enter the gas phase. Because the free paths of light and heavy molecules are different, molecules of different substances move at different distances after escaping from the liquid surface. If a condensing plate can be properly set up, light molecules will reach the condensing plate and be condensed and discharged, while heavy molecules will not reach the condensing plate and be discharged along the mixed liquid.

Product Features

- Thermal separation of heat-sensitive compounds.

- Purification of organic synthetic substances.

- Purification of active ingredients in biological extracts.

- Recycling of industrial waste.

- Removal of toxic substances in the food industry.

- Decolorization and odor removal of organic compounds.

- Thorough removal of residual solvents in the compound.

Product Application

- Chinese and Western medicines: antibiotics, sugar solution, Tripterygium wilfordii,Astragalus and other Chinese herbal medicines; Methylimidazole, mononitrile amine and other intermediates;

- Light industrial food: fruit juice, gravy, pigment, flavor, spice, enzyme preparation, lactic acid, xylose, starch sugar, potassium sorbate;

- Grease daily chemicals: lecithin, VE, cod liver oil, oleic acid, glycerin, fatty acid, waste lubricating oil, alkyl polyglycoside, alcohol ether sulfate, etc.;

- Synthetic resin: polyamide resin, epoxy resin, paraformaldehyde, PPS (polypropylene sebacate), PBT, propylene formate;

- Synthetic fiber: PTA, DMT, carbon fiber, polytetrahydrofuran, polyether polyol, etc.;

- Petrochemical: TDI, MDI, trimethylhydroquinone, trimethylolpropane, sodium hydroxide, etc.;

- Pesticide biology: acetochlor, pretilachlor, chlorpyrifos, furanol, clomazone, and other herbicides, insecticides, herbicides, and acaricides;

- Wastewater: inorganic salt wastewater, etc.;

Product Advantages

- The heating time of the material is short.

- Low evaporation temperature.

- High evaporation efficiency.

- Continuous feeding and discharging.

- Made of corrosion-resistant 316 stainless steel.

- The heat transfer rate is fast.

Product Parameters

| Stainless Steel Molecular Distillation | ||||||||||

| Model | FMD-0.1SS | FMD-0.15SS | FMD-0.25SS | FMD-0.35SS | FMD-0.5SS | FMD-1SS | FMD-1.5SS | FMD-2SS | FMD-3SS | FMD-5SS |

| Effective evaporation area(m2) | 0.1 | 0.15 | 0.25 | 0.35 | 0.5 | 1 | 1.5 | 2 | 3 | 5 |

| Condensing area(m2) | 0.17 | 0.3 | 0.4 | 0.7 | 1.7 | 2.7 | 3.5 | 4.9 | 6.5 | 8 |

| Feeding speed(L/H) | 5-12 | 6-15 | 10-25 | 15-30 | 20-60 | 50-120 | 60-180 | 100-200 | 100-300 | 200-500 |

| Rotate speed(r/min) | 30-350 | |||||||||

| Stainless steel material | 304/316 | |||||||||

| Feeding method | Gear pump automatic continuous feeding | |||||||||

| Discharge method | Gear pump automatic continuous discharge | |||||||||

| Operating Temperature(℃) | Within 350℃ | |||||||||

| Voltage | 220V/60Hz

Other voltages can be customized |

|||||||||

Product Details

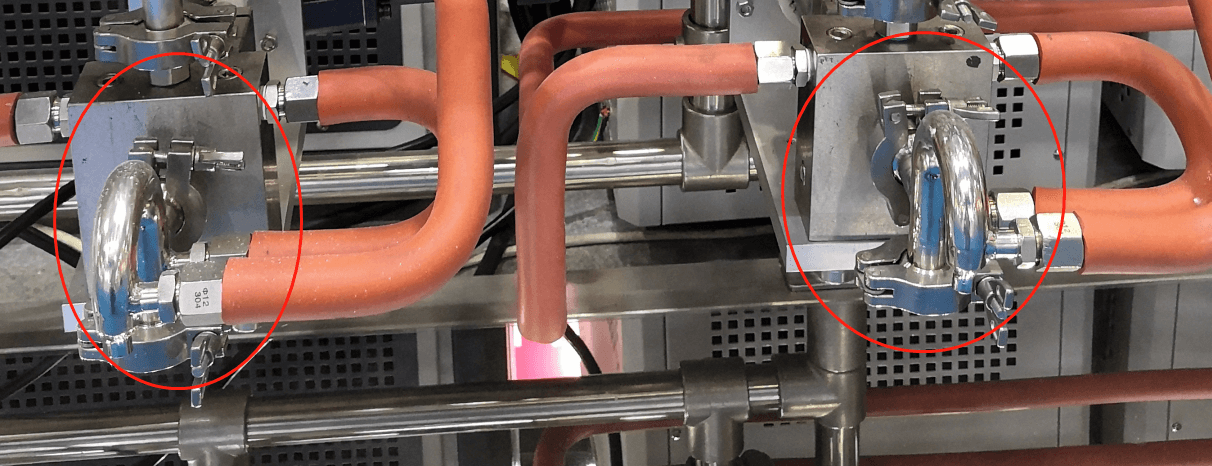

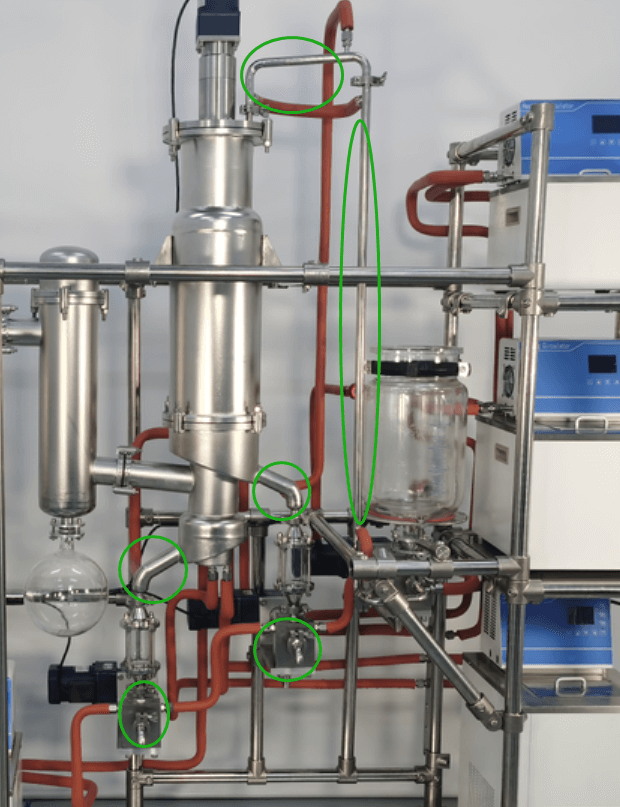

1.The gear pump is used for continuous feeding.

2.The gear pump is used for continuous discharging.

3.Jacketed conveying pipeline has good heat preservation effect.

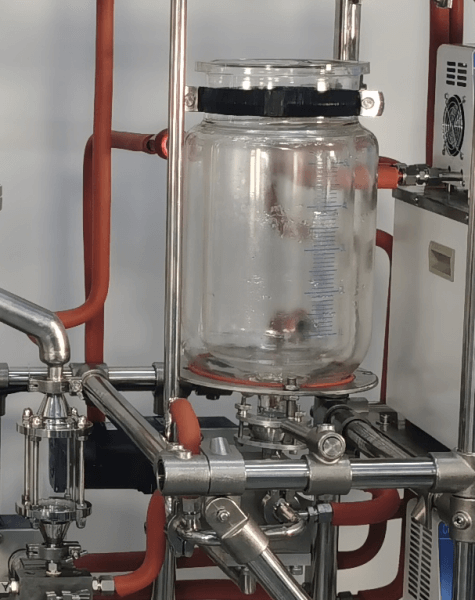

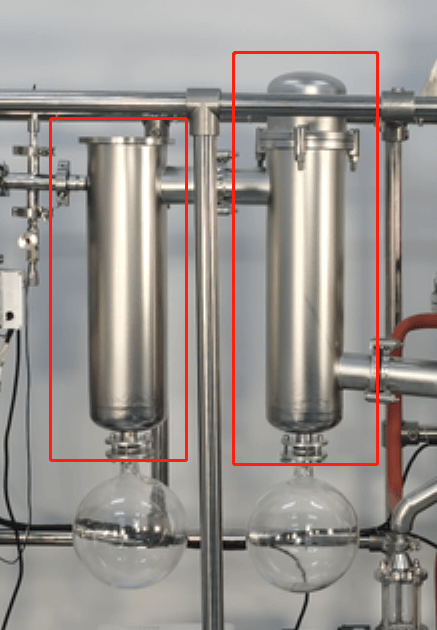

4.The cooling system adopts serpentine condenser and cold trap.

5.The evaporator is made of high-quality stainless steel, which has fast heat transfer, high efficiency and durability.

FAQ

- Q: How long is the lead time for a single unit?

A: 20 days under normal conditions.

- Q: What material is the standardequipment, and can other materials be provided?

A: Standard 316 material.

- Q: How much vacuum can be achieved?

A: No load 0.1Pa, and about 20Pa when working.

- Q: Can other structures be customized?

A: Yes.

- Q: Compared with glass molecular distillation, what are the advantages of stainless steel molecular distillation?

A: The heat transfer efficiency is high, and it is not easy to be damaged.

Matching Products

- Short-path distillation

- Glass molecular distillation

glass molecular distillation

After-sales Service

After-sales service principle:

- Timely

- Professional

- Efficient

- Cooperative

The process of after-sales problem service:

- After the sales staff receives the customer’s feedback, they will respond to the customer’s questions in a timely manner.

1.1 Sales personnel need to deal with customer feedback in a timely manner, and propose solutions to customers within 24 hours.

1.2 If the customer’s feedback needs to be transferred to the after-sales personnel for processing, the after-sales problem feedback information form will be sent to the after-sales personnel within 24 hours, and the after-sales personnel will formally intervene to deal with the customer’s problems.

- After the after-sales personnel receive the information form, they will ask the salesperson to understand the specific situation of the customer within 24 hours; at the same time, the salesperson is responsible for forming the whatsapp group of customers, after-sales personnel, and general managers.

- After-sales personnel communicate directly with customers through email and whatsapp, learn more about the problems encountered by customers, and make appointments for video call time with customers within 3 working days.

- Check the product equipment through the first video call and initially confirm the equipment failure, and propose effective solutions.

4.1 If the equipment can be repaired through the simple operation of the customer, the operation plan will be sent to the customer within 24 hours after the video. Wait for the customer to make preparations and make an appointment for the second video call to guide on-site maintenance work.

4.11 If the equipment is repaired, the after-sales work is completed.

4.12 If the equipment is not repaired, propose a solution for the second time. Refer to 4.1 and 4.2 for the process. The equipment is repaired and the after-sales work is completed.

4.2 If the customer needs to ask a technician for on-site repair in the local area, the preparation work and repair process before the on-site repair will be sent to the customer within 24 hours after the video. And at the time of the technician’s door-to-door visit, we will also conduct a video call with the customer to guide the on-site maintenance work.

4.21 If the equipment is repaired, the after-sales work is completed.

4.22 If the equipment is not repaired, a solution is proposed for the second time. Refer to 4.1 or 4.2 for the process. After the equipment is repaired, the after-sales work is completed.

4.3 If the customer needs to replace the parts, the after-sales staff will notify the sales staff to reissue the parts through the Fortis customer management module or Dingding within 12 hours after the video. The salesperson fills in the after-sales problem order form within 24 hours after receiving the information, and informs the customer of the delivery progress at the same time. After the customer receives the accessories, refer to 4.1 or 4.2.

4.31 If the equipment is repaired, the after-sales work is completed.

4.32 If the equipment is not repaired, refer to 4.12 or 4.22.

- After the after-sales service is over, the sales staff will send the after-sales service evaluation form to the customer and invite the customer to evaluate the after-sales work.

Purpose: solve the problem of the customer’s equipment within three videos.

Packing and Delivery

Reviews

There are no reviews yet.