Description

The S212 double-layer glass reactors adopt double-layer glass design. The reaction solvent is put in the internal layer to do the stirring reaction, and different cold and heat sources (refrigerating fluid, hot water or oil) can be connected to the interlayer to do circulating heating or cooling reaction. Under the condition of the given constant temperature, the stirring reaction can be done under normal or negative pressure in a closed glass reactor, as well as the backflow and distillation of the reaction solution. It is an ideal pilot-plant and production equipment for modern fine chemical industry, bio-pharmaceutical and new material synthesis.

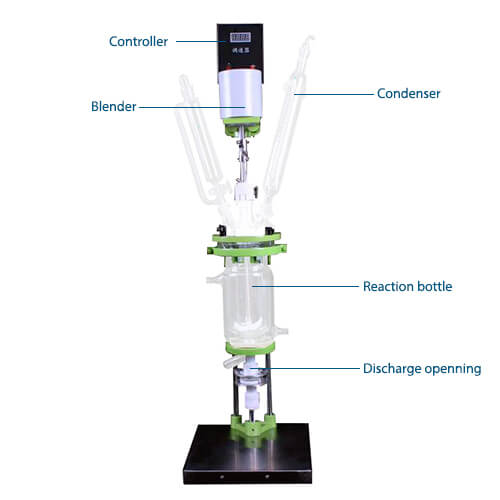

Under the condition of the given constant temperature, the stirring reaction can be done under normal or negative pressure in a closed glass reactor, as well as the backflow and distillation of the reaction solution. The S212-5L double-layer glass reactor is an ideal pilot-plant and production equipment for modern fine chemical industry, biopharmaceuticals and new material synthesis. The glass reactor series mainly contains following parts: the double-layer glass reaction kettle, a set of component cover of the glass reactor, condensers, a constant voltage funnel, a frequency conversion controller, the rotary stirring and sealing system, the stainless steel frame system, etc.

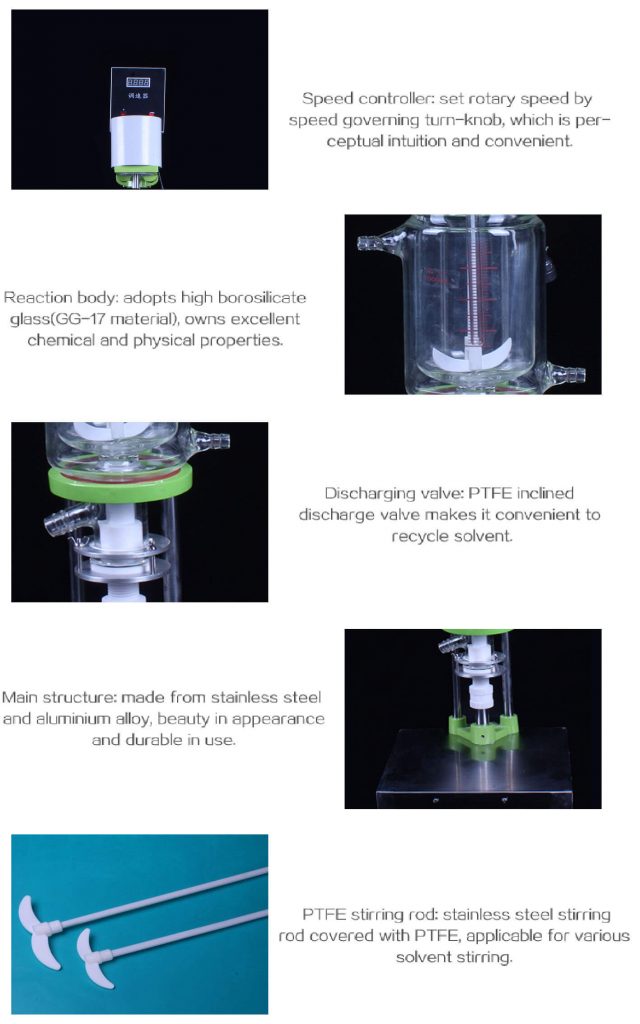

Product Features

- The kettle body is made of high borosilicate glass (G-17 material), with excellent physical and chemical properties. And it is convenient to observe the reaction liquid with a transparent kettle body.

- The main body adopts both stainless steel and aluminum alloy, which is elegant, sturdy and anti-corrosion.

- The out layer of the stainless steel stirring rod is wrapped with PTFE, which is applicable for stirring a variety of solvents without pollution and corrosion.

- The AC motor is adopted to stir, featuring stable operation, large torque, no spark and long service life.

- The PTFE components and fluororubber sealing technology can guarantee a good vacuum degree and long service life.

- The product is equipped with a speed governor. The rotating speed can be set through the speed control knob, intuitive and convenient.

- The product can display the vacuum degree so that the optimal vacuum degree can be selected for materials with low boiling point.

- With a PTFE inclined discharge valve, it’s fast and convenient to recycle solvents.

Product Advantages

Constant rotating speed, no brush, no spark, safe and stable, work continuously.

Product Parameters

| Basic Parameters | Model | Single layer glass reactor |

| Volume of the reactor bottle | 5L | |

| Glass material | GG-17 | |

| Main body | Stainless steel | |

| Number of covered bottle | 5 | |

| Reaction temperature of the reactor | -80-250℃ | |

| Degree of vacuum | 0.098Mpa | |

| Stirring speed | 0-800pm | |

| Stirring shaft diameter | 8mm | |

| Motor Power | 90W | |

| Heating power | 2KW | |

| Voltage/Hertz | 220V/50Hz | |

| Whole size | 430*330*1200mm | |

| Plate size | 410*325mm | |

| Pot gall size | Stainless steel 280*170mm | |

| Packing size | 1000*480*480 | |

| Packing weight | 30kg | |

| Function Device | Speed regulation method | Electronic variable speed |

| Rotating speed display mode | Number display | |

| Pot temperature display mode | Number display | |

| Sealing method | PTFE material seal,¢50 Flange stirring port | |

| Condenser | Vertical 60*450mm 24#Standard port | |

| Drop wise | 500ml Constant pressure funnel 29#Standard port | |

| Pressure reduce device | 24# standard port pressure reduce valve | |

| Temperature test tube | 24#Standard port | |

| Collecting device | Two adapter headband with collection bottle | |

| Vacuum display method | Vacuum table | |

| Stirring connection method | Universal joints | |

| Stir bar | Described stainless steel rods, outsourcing PTFE | |

| Optional Device | Explosion-proof | Explosion-proof inverter/Explosion proof motors EX60W 0-1400rmp |

| Kettle temperature display | Optional digital display | |

| Discharge device | PTFE discharge valve flange ¢ 60 | |

| Heating device | electric heating jacket heating | |

| Our laboratory equipment can be customized according to customers actual needs . | ||

Product Parts

Product Details

Reviews

There are no reviews yet.