Description

S212-50L double-layer glass reactor’s reaction flask volume is 50L, interlayer volume is 12L, stirring diameter of axle is 12mm, and the power of stirring is 120W.

Product Details

Product Parameters

|

Basic Parameter |

Type |

S212-50L |

|

Glass material |

GG-17 |

|

|

Frame material |

Stainless Steel |

|

|

Pipe fitting material |

304 Stainless Steel |

|

|

Move method |

Universal castors with braking |

|

|

Reaction flask volume |

50L |

|

|

Interlayer volume |

12L |

|

|

Flange type oil in and out circulation port |

Enter from low port, come out from high port |

|

|

Number of reactor bottle |

6 | |

|

Discharge outlet liftoff height |

450mm |

|

|

Reactor reaction temperature |

-80-250 degree |

|

|

Vacuum degree |

0.098Mpa |

|

|

Stirring speed |

0-450rpm |

|

|

Stirring diameter of axis |

12mm |

|

|

Stirring power |

120W1/3 |

|

|

Voltage/Frequency(V/Hz) |

220V/50Hz |

|

|

Boundary dimension(mm*mm*mm) |

760*560*2450 |

|

|

Package Dimension(mm*mm*mm) |

1720*680*850 0.99m³ |

|

|

Package weight(KG) |

92 | |

Functional Configurations

|

Speed adjustment mode |

Electric stepless speed regulation |

|

Electrical machine configuration |

Low speed reinforcement electrical machine, speed ratio 3:1 |

|

|

Rotate speed display mode |

Liquid crystal digital display |

|

|

Temperature display mode |

PT100 sensor digital display |

|

|

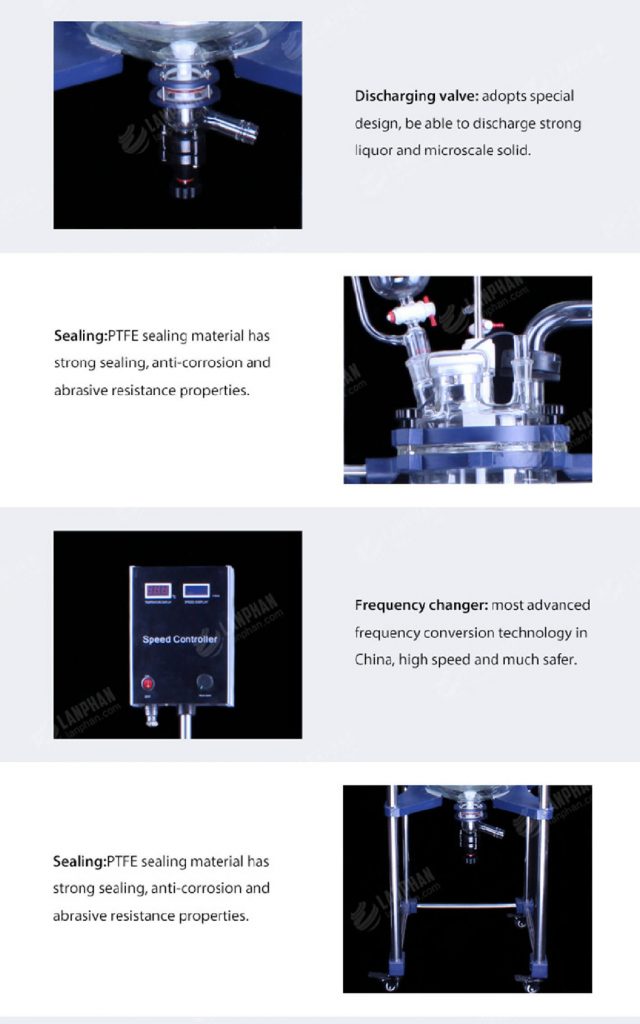

Sealing mode |

PTFE sealing, ¢50 flange stirring mouth |

|

|

Condenser |

Vertical high efficiency double backflow condenser pipe 120*640mm, 40# standard mouth |

|

|

Backflow (distillation) device |

Backflow elbow is equipped with discharge switch, 50# ball milling mouth |

|

|

Dropwise adding device |

2K constant voltage funnel, 40# standard mouth |

|

|

Depression device |

34# standard mouth reducing valve |

|

|

Temperature testing tube |

24# standard mouth |

|

|

Solid charging |

¢80 flange mouth with PTFE cover |

|

|

Discharging method |

Inclined glass discharging valve, ¢80 flange mouth |

|

|

Vacuum display mode |

Vacuum meter |

|

|

Stirring connecting method |

Universal joint connecting |

|

|

Stirring bar |

Anchor type stainless steel bar, covered with PTFE |

|

Optional Configurations

|

Main body support |

Tray type |

|

Collecting device |

Collection bottle |

|

|

Anti-Explosion |

Anti-explosive frequency changer, anti-explosive electric machine EX180W 0-1400 rotate |

|

|

Frame part |

Spraying plastics pr PTFE |

|

|

Heat insulation device |

Cotton insulation |

|

|

Sealing part |

Ceramic bearing, mechanical sealing |

|

|

Condenser |

Horizontal type condenser can reduce overall height |

|

|

Reactor cover |

Custom-made PTFE reactor cover |

Pre-Sale Service

- Provide 24-hour technical consultation and reply;

- Provide professional quotation information;

- Provide detailed product performance specification;

- According to product’s using condition, technicians will offer rationalization proposals to assist clients to select proper product types;

- Provide other corollary equipment according to client requirements.

In-Sale Service

- With supervision from the source of products, the qualified rate of raw materials entering the factory can reach 100%;

- Whole manufacturing process are in strict accordance with promised procedure requirements, product qualified rate can reach100%;

- Provide product’s inspection record of key junctures to customers;

- Provide production schedule photos to customers at regular intervals;

- Package and transport of products are in strictaccordance with the export standard;

- Provide transportation schedule information to clients timely.

After-Sale Service

- Provide targeted installation video;

- Under the premise of correct installation, normal maintenance and using, we guarantee one-year warranty period;

- When warranty period has expired, our sold products enjoys lifetime guarantee repair, we only charge cost price for changing product’s standard component and sealing component;

- During installation and adjustment period, our after-sale service staff will communicate with customers frequently to know product’s running state in time. Assist customers to install and adjust products until customers are satisfied;

- If product has malfunction during operation period, we’ll offer you satisfied answer in time. We’ll reply you within 1 hour and provide solution or send staff to spot within 24 hours after receiving maintenance notification;

- Lifelong free technical support. Conduct satisfaction survey and inquiry equipment running condition to clients by telephone or e-mail semiannually from the first day of equipment running, put on records of acquired information;

- Provide assistance in solving problems such as equipment damage in the transport.

Reviews

There are no reviews yet.