Description

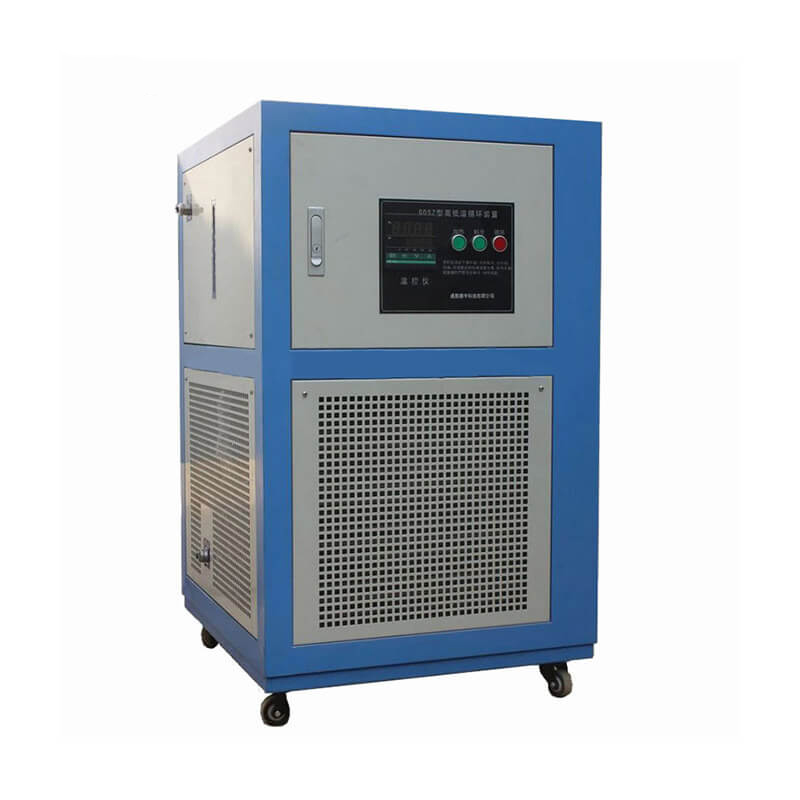

Product Description

In the entire system of the GDSZ series High and Low Temperature Circulation Device, the liquid circulation is sealed. The system has an expansion vessel that does not participate in the liquid circulation and is insulated from the liquid circulation, just a mechanical connection. Regardless of whether the temperature of the liquid circulation is high or low, the medium in the expansion vessel is less than 60 degrees. The entire liquid circulation is a closed system. There is no inhalation of water vapor at low temperatures, no oil mist at high temperatures, and the heat transfer oil can have a wide operating temperature.

Precautions for Use

Please confirm the power ,voltage and phase for correct connection and have the reliable ground wire!

To avoid electrical shock, please don’t connect the ground wire with gas or water pipe!

Put the equipment in a ventilated, dry , non-pollution place, which has a distance from separator more than 700mm, and the air filter must not be blocked!

Please add some corresponding oil before using according to the temperature. Do not add fiber content, and keep the oil in line at running time!

Do not use it in the combustible, explosive, corrosive gas in the environment !

Frequent start compressor can affect life, so the number of starts per hour should be less than 5 times, and each time the downtime should be more than 5 minutes !

Please confirm the reliable connection. Once the connection gets lost or leaked , it can cause burning and freezing.

Please do the simulation of test technology before opening to be confirmed if the machine is able to meet the technological requirements, and then put into normal use!

Use temperature must be in line with the specified temperature range !

There is the high pressure gas in the closed cooling system, so non-professionals can not open it !

Heating less liquid or non-liquid is strictly prohibited !

Running with fault is strictly prohibited, because it can damaged more parts, or even endanger personal security.

Product Instructions

Please connect this device’s outlet to the inlet of the reactor, and connect this device’s inlet of the equipment to the outlet of the reactor to make it a closed loop system with the reactor.

The equipment adopts three-phase five-wire system (three fire wires, one neutral wire and one ground wire) to connect the power supply. If the phase sequence is in error (the phase sequence protector indicator in the circuit is red), swap any two live line positions until the phase sequence protector indicator is green.

Open the top cover of the refill tank, add the heat transfer oil to the middle oil level of the expansion vessel liquid level indicator; open the exhaust valve, turn on the power, press the liquid button to start adding heat transfer medium to the system. Until there is liquid overflowing from the exhaust port. (At this point, most of the gas in the system has been removed).

Close the exhaust valve, turn on the “run button”, set the temperature to 150 degrees, and continue to exhaust. After reaching 150 degrees, reset the temperature to 25 degrees. Run back and forth twice.

After the total dosing is completed, the liquid level of the expansion tank at 25 degrees shall be at the specified liquid level and shall not exceed or fall below the calibration level. (Exhaust valve closed)

Product Parameter

| Product Name | High and Low Temperature Circulation System |

| Product Model | GDSZ-20 |

| Matching Reactor Volume | 20L |

| Storage Tank Volume | 20L |

| Optimum Environment Temperature | ≤25℃ |

| Environment Humidity | ≤60℃ |

| Voltage | 220V±10% 50HZ |

| Heating Power | 2000W |

| Temperature Accuracy | ±0.1℃ |

| Sensor | PT100 |

Matching Products

Certification

Packing and Shipping

Reviews

There are no reviews yet.