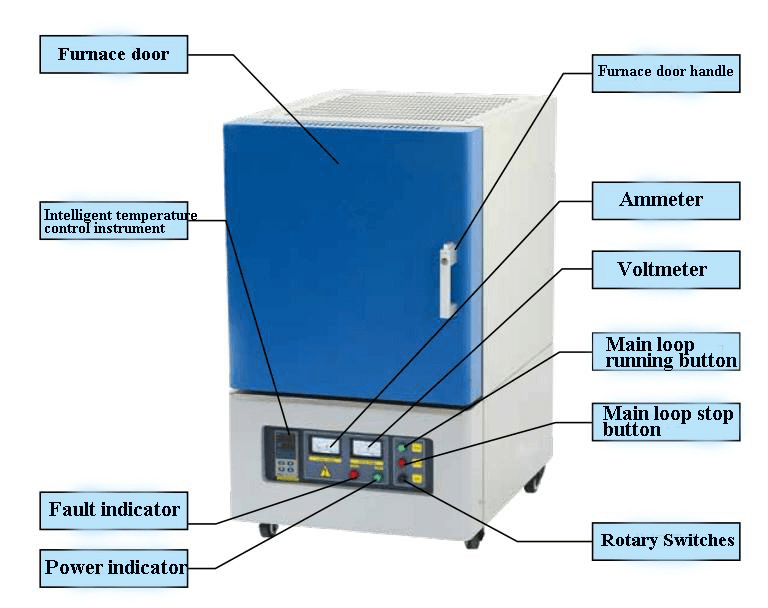

Description

The muffle furnace is a universal heating equipment, which can be divided into box furnace, tube furnace and crucible furnace according to its appearance.

The muffle furnace is a cyclic operation type. It is used for the element analysis and determination of laboratories, industrial and mining enterprises, and scientific research units and for heating during the quenching, annealing and tempering of general small steel parts. The high-temperature muffle furnace can also be used for the sintering, dissolution, analysis and other high temperature heating of metals and ceramics.

Working Principle

The working principle of the box-type high-temperature sintering furnace (SX2 series): After the temperature measuring element thermocouple converts the temperature into an electrical signal (voltage), it is connected to the microcomputer temperature controller. The temperature controller compares this signal with the programmed value, and then the microcomputer generates a control signal that reflects the temperature change of the furnace after calculating the difference, the positive and negative values, and the time. Use this signal to drive electrical components (power modules, solid-state relays, AC contactors, etc.) to achieve the purpose of controlling the furnace temperature. The high-precision PID program is used to automatically control the entire process and digitally display the furnace temperature and process information.

According to the different heating elements used, three temperature ranges are reached, namely 1200℃ 1400℃, and 1700℃. At 1200℃, molybdenum-containing resistance wires are used as heating elements. At 1400℃, silicon carbide rods are used as heating elements. At 1700℃, silicon molybdenum rods are used as heating elements.

Product Application

(1) Thermal processing, industrial workpiece processing, cement, building materials industries, and thermal processing or treatment of small workpieces.

(2) Pharmaceutical industry: used for drug inspection, pretreatment of medical samples, etc.

(3) Analytical chemistry industry: as sample processing in water quality analysis, environmental analysis and other fields. It can also be used for petroleum analysis.

(4) Coal quality analysis: used to determine moisture, ash, volatile content, ash melting point analysis, ash composition analysis, element analysis. Can also be used as a general ashing furnace.

Product Features

- 30-segment intelligent temperature control regulator, PID control, temperature control accuracy is ±1 degree.

- The temperature upper limit alarm can be set, and the main circuit can be automatically cut off when the temperature exceeds the upper limit.

- Using high-purity alumina ceramic fiber as the furnace material, and the thermal insulation effect is good.

- Different furnace chamber sizes can be customized according to customer requirements.

- Simple air inlets, exhaust outlets and observation windows can be added according to customer requirements.

Product Classification

- According to the heating elements, it is divided into: electric furnace wire muffle furnace, silicon carbide rod muffle furnace, silicon molybdenum rod muffle furnace.

- According to the operating temperature, it is divided into: low temperature muffle furnace (electric furnace wire muffle furnace below 1000℃), medium temperature muffle furnace (silicon carbide rod muffle furnace 1100 ~ 1300℃), high temperature muffle furnace (silicon molybdenum rod muffle furnace 1700℃).

- According to the insulation materials, it is divided into two types: ordinary refractory brick muffle furnace and ceramic fiber muffle furnace.

Product Advantages

①Adopt advanced AI(artificial intelligence) adjustment algorithm, no overshoot, with self-tuning function, can realize any slope rise and drop temperature control, with jump (cycle), run, pause, stop and other programmable/operable commands.

②The input and output adopt digital correction system, the measurement is accurate and stable, and it can be extended to use non-linear sensors with any index number.

③The second-order digital filtering function and watchdog circuit can maintain accurate measurement and stable work even in a strong interference environment.

④Measurement accuracy: 0.2 level.

⑤Alarm function: upper limit, input open circuit.

⑥ 30/50 segment program control function.

⑦Power-down protection: Due to the EPROM chip, various input data can be reliably saved even when the meter is powered off or interfered.

⑧Power supply: 100 ~ 240VAC 50 ~ 60Hz.

⑨Power consumption: ≤ 5W.

Product Parameters

| Model | Maximum temperature(℃) | Furnace size(mm) | Input power(V/KW) |

| SX2-1-12TP | 1200℃ | 100X100X100 | 220V/1KW |

| SX2-2-12TP | 1200℃ | 200X150X150 | 220V/2KW |

| SX2-6-12TP | 1200℃ | 300X200X200 | 220V/6KW |

| SX2-9-12TP | 1200℃ | 400X300X300 | 220V/9KW |

| SX2-2-14TP | 1400℃ | 100X100X100 | 220V/2KW |

| SX2-4-14TP | 1400℃ | 200X150X150 | 220V/4KW |

| SX2-7-14TP | 1400℃ | 300X200X200 | 220V/7KW |

| SX2-16-14TP | 1400℃ | 400X300X300 | 380V/16KW |

| SX2-2-17TP | 1700℃ | 100X100X100 | 220V/2KW |

| SX2-4-17TP | 1700℃ | 200X150X150 | 220V/4KW |

| SX2-9-17TP | 1700℃ | 300X200X200 | 380V/9KW |

| SX2-16-17TP | 1700℃ | 400X300X300 | 380V/16KW |

Installation Precautions

- Do not place it on an uneven or vibrating site, otherwise it will easily cause the equipment to be unstable and tip over.

- Do not put flammable and explosive materials near the furnace body, otherwise there is a danger of explosion.

- Do not drop screws, gaskets and other metal objects into the equipment, otherwise it may cause a short circuit or fire in the equipment.

- Do not place it in a place where water is easy to splash. If water enters the product body, it may cause fire and electric shock.

- The equipment should be installed in an environment where there is no gas or steam that is conductive, dust-free, and does not damage the insulation performance.

- The place of placement should be a place with air circulation, no vibration, no impact, and no high dust.

Safe Operation and Maintenance

- Because the refractory contains moisture, and in order to generate an oxide layer on the heating element, when the muffle furnace is used for the first time or is not used for a long time, it must be heated and dried in an oven to prevent the furnace from cracking due to the rapid temperature changes after being damp. The specific operation is: open the oven door and bake for 2-3h at 20~200℃, and close the door for 2-3h at 200~600℃.

- The furnace temperature should not exceed the rated temperature, so as not to damage the heating elements and the furnace. It is forbidden to directly pour liquid or molten metal into the furnace. Frequently remove the metal and oxidation residues in the furnace to keep the furnace clean.

- Please lock the furnace door before heating. It is not recommended to open the furnace door when the temperature in the furnace is greater than 400℃;

- Regularly check whether each electrical connection part of the temperature control system is in good contact, especially the connection of each connection point of the heating element;

- Recommended heating rate: <1000℃, 10℃/min; 1000-1500℃, not exceeding 5℃/min; after 1500℃, not exceeding 2℃/min, otherwise the furnace and heating elements will be damaged.

- When the equipment is cooling down, please use the program to cool down and set the cooling program. It is not recommended to directly “stop” to cool down. For a high-temperature furnace of 1800℃, the cooling rate is recommended not to exceed 3℃/min, otherwise the furnace will be damaged. Please do not turn off the power of the device if the temperature of the device is above 500℃ to prevent safety problems.

- After several cycles of heating, the insulating material in the furnace may crack. This is caused by thermal expansion and has no effect on the quality of the furnace.

- The equipment must be reliably grounded when connected to the power source, otherwise there is a danger of electric shock.

- The power supply of the equipment must be connected to the corresponding air switch.

Maintenance Precautions

Note: After the power is supplied, you should hear the “wheezing” sound of the cooling fan. If there is no such sound, immediately stop the machine and check and replace the cooling fan. Fan specifications: Axial fan AC220v/120×120mm.

When the furnace is used for the first time or left unused for a long time, or the working environment is relatively humid, the furnace chamber of electric furnace should be dried first to avoid cracks in the furnace, which will affect the heat preservation effect. Open the oven door and bake for 2-3h at 20~200℃, and close the door for 2-3h at 200~600℃.

- When the furnace is in use, the input power must not exceed the rated power, and the furnace temperature must not exceed the rated temperature, so as not to damage the heating element and the furnace lining. It is forbidden to directly pour various liquids and dissolved metals into the furnace, and keep the furnace tube clean.

- The heating rate of each temperature zone is not easy to be too different. When setting the heating rate, the physical and chemical properties of the sintered material should be fully considered to avoid the phenomenon of material spraying and polluting the furnace.

- Regularly check whether the electrical connection part of the temperature control system is in good contact.

- This furnace is suitable for the following working conditions:

(1) The ambient temperature is between -10 and 75℃.

(2) The relative humidity of the surrounding environment does not exceed 85%.

(3) There is no conductive dust, explosive gas or corrosive gas that can seriously damage metals and insulating materials around the furnace.

(4) There is no obvious tilt, vibration and bumps.

Common Faults and Solutions

| Failures | Causes | Solutions |

| Turn on the control power switch LOCK, but no power indication | The fuse of control line FU1 2A is broken | Check whether there is short circuit, and replace the fuse after elimination |

| The green POWER indicator is off, and the red OPEN CIRCUIT indicator is on. | The fuse of main circuit FU2 32A is broken | Check whether there is short circuit, and replace the fuse after elimination |

| Maximum voltage, but no current. | Resistance wire fracture | Replace the electric furnace wire |

| Meter SV alternately displays Oral | Thermocouple break | Replace the thermocouple |

| Meter SV alternately displays HIAL | The furnace body exceeds the upper limit temperature | When the temperature drops to the safe temperature, the meter automatically returns to normal (check the cause of overtemperature) |

| Power supply and resistance wire are normal, but the furnace body can not be heated | The control circuit is damaged | Inform professional maintenance personnel |

Matching Products

1、Crucible tong

2、High temperature gloves

Packing and Delivery

Pre-Sale Service

- Provide 24-hour technical consultation and reply;

- Provide professional quotation information;

- Provide detailed product performance specification;

- According to product’s using condition, technicians will offer rationalization proposals to assist clients to select proper product types;

- Provide other corollary equipment according to client requirements.

In-Sale Service

- With supervision from the source of products, the qualified rate of raw materials entering the factory can reach 100%;

- Whole manufacturing process are in strict accordance with promised procedure requirements, product qualified rate can reach100%;

- Provide product’s inspection record of key junctures to customers;

- Provide production schedule photos to customers at regular intervals;

- Package and transport of products are in strictaccordance with the export standard;

- Provide transportation schedule information to clients timely.

After-Sale Service

- Provide targeted installation video;

- Under the premise of correct installation, normal maintenance and using, we guarantee one-year warranty period;

- When warranty period has expired, our sold products enjoys lifetime guarantee repair, we only charge cost price for changing product’s standard component and sealing component;

- During installation and adjustment period, our after-sale service staff will communicate with customers frequently to know product’s running state in time. Assist customers to install and adjust products until customers are satisfied;

- If product has malfunction during operation period, we’ll offer you satisfied answer in time. We’ll reply you within 1 hour and provide solution or send staff to spot within 24 hours after receiving maintenance notification;

- Lifelong free technical support. Conduct satisfaction survey and inquiry equipment running condition to clients by telephone or e-mail semiannually from the first day of equipment running, put on records of acquired information;

- Provide assistance in solving problems such as equipment damage in the transport.

Reviews

There are no reviews yet.