Description

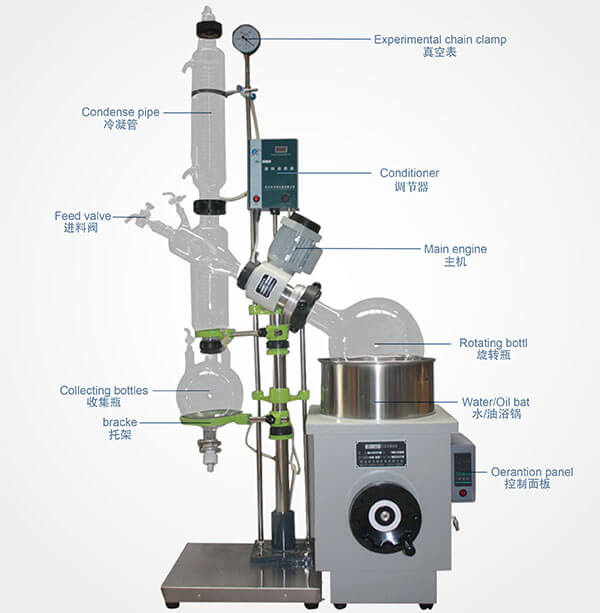

Product Description

Product Parts

Intelligent digital display lifting water and oil universal bath, stainless steel one-time forming liner without welding, annular heating tube heating evenly, heating rate is high.

Product Parameters

| Basic Parameter | Type | RE-1002 |

| Glass Material | GG-17 | |

| Support Material | stainless steel | |

| Shell Material | Antisepsis Plastic Spraying 490*430*540mm | |

| Inner Container Material | stainless steel 350*220mm | |

| Baseboard Size | 474*474mm | |

| Volume of Rotary Bottle | 10L ¢95 flange aperture | |

| Volume of Recycling Bottle | 5L ¢50 flange aperture | |

| Vacuum Degree | 0.098Mpa | |

| Rotating Power | 120W | |

| Rotating Speed | 0-110rpm | |

| Heating Power | 3KW | |

| Temperature Control Range of Bath Kettle | 400℃ | |

| Temperature Accuracy | ±1℃ | |

| Voltage/Frequency (V/Hz) | 220V/50Hz | |

| Up and Down Distance | 180mm | |

| Shape Size(mm*mm*mm) | 970*480*1950mm | |

| Package Weight (KG) | 100 | |

| Function Allocation | Speed Adjustment Mode | Electrodeless Speed Regulation |

| Rotate Speed Display Mode | Digital Display | |

| Temperature Display Mode | Digital Display K Type Sensor | |

| Temperature Control Mode | Smart Temperature Control | |

| Sealing Mode | PTFE Sealing | |

| Condenser | Vertical efficient condenser, main condenser 120*640, assistant condenser 135*470 | |

| Up and Down Mode | Manual Up and Down of Bath Kettle | |

| Continuous Charging | Standard Aperture Feeding Valve | |

| Vacuum Display Mode | Vacuum Meter | |

| Continuous Collecting | Check valve control | |

| Charging Mode | PTFE Charging valve, ¢50 flange aperture | |

| Optional Equipping | Up and Down Mode | Automatic Up and Down |

| Collecting Device | Double Recycling bottle | |

| Anti-explosion | Anti-explosion Frequency Changer, Anti-explosion Dynamo EX120W | |

| Frame Part | Plastic Spraying or PTFE Spraying | |

| Bath Kettle Material | whole 304 stainless steel | |

| Our company’s laboratory glass and laboratory instruments are independent research and development, available for custom-made according to client requirements. | ||

Packing List

| Machine Part | Glass Part | ||

| Nose | 1 set | Rotary bottle | 1 unit |

| Floor shelf | 1 set | Recycling bottle | 1 unit |

| Aluminum Backing Ring of Assistant Condenser | 1 unit | Main condenser | 1 unit |

| Vacuum meter | 1 pc | Air conduction bottle | 1 unit |

| Rotary nut | 1 set | Feeding Valve | 1 unit |

| Assistant condenser nut | 1 set | ¢60 flange tap | 1 unit |

| PTFE sealed joint sleeve | 1 set | 24# vent valve | 2 units |

| PTFE feeding valve with flange plate | 1 set | 19# vent valve | 1 unit |

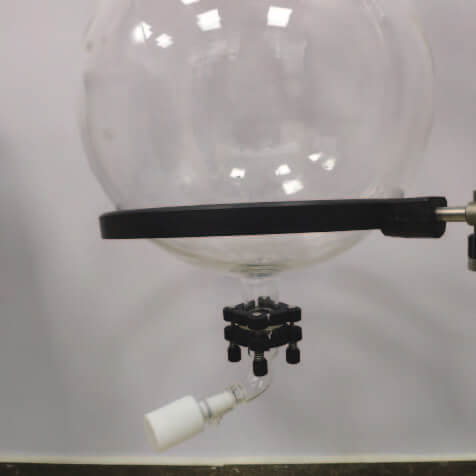

| Check valve | 1 set | Rotary shaft | 1 unit |

| Aluminum Backing Ring of recycling bottle | 1 unit | Assistant Condenser | 1 unit |

| ¢60F4 pad | 3 units | ||

| ¢80F4 pad | 1 unit | ||

| Big black hat | 3.5 sets | ||

| Transducer | 1 set | ||

| Water bath kettle | 1 unit | ||

| Condenser pipe clamp | 1 unit | ||

| The final interpretation of this operation manual is reserved by our company. If any change in product, please be subject to the real product. The operation manual will not be changed. | |||

[title style=”center” text=”Quality Certification” tag_name=”h2″ color=”rgba(32, 163, 219, 0.81)”]

Pre-Sale Service

- Provide 24-hour technical consultation and reply;

- Provide professional quotation information;

- Provide detailed product performance specification;

- According to product’s using condition, technicians will offer rationalization proposals to assist clients to select proper product types;

- Provide other corollary equipment according to client requirements.

In-Sale Service

- With supervision from the source of products, the qualified rate of raw materials entering the factory can reach 100%;

- Whole manufacturing process are in strict accordance with promised procedure requirements, product qualified rate can reach100%;

- Provide product’s inspection record of key junctures to customers;

- Provide production schedule photos to customers at regular intervals;

- Package and transport of products are in strictaccordance with the export standard;

- Provide transportation schedule information to clients timely.

After-Sale Service

- Provide targeted installation video;

- Under the premise of correct installation, normal maintenance and using, we guarantee one-year warranty period;

- When warranty period has expired, our sold products enjoys lifetime guarantee repair, we only charge cost price for changing product’s standard component and sealing component;

- During installation and adjustment period, our after-sale service staff will communicate with customers frequently to know product’s running state in time. Assist customers to install and adjust products until customers are satisfied;

- If product has malfunction during operation period, we’ll offer you satisfied answer in time. We’ll reply you within 1 hour and provide solution or send staff to spot within 24 hours after receiving maintenance notification;

- Lifelong free technical support. Conduct satisfaction survey and inquiry equipment running condition to clients by telephone or e-mail semiannually from the first day of equipment running, put on records of acquired information;

- Provide assistance in solving problems such as equipment damage in the transport.

Error: Contact form not found.