Description

What is a Vacuum Evaporation Concentrator?

A vacuum evaporation concentrator is a device used to reduce the volume of liquids by evaporating water and other volatile components. The concentrated liquid is then collected in a smaller volume for further processing or storage. Vacuum evaporation concentrators are often used in the food industry for the concentration of fruit juices and other food products, as well as in the chemical industry for the concentration of solvents and other chemicals.

What is the difference between concentrator and evaporator?

The main difference between a concentrator and an evaporator is that a concentrator is used to concentrate a solution by removing the solvent, whereas an evaporator is used to reduce the volume of a liquid by evaporating the solvent. The evaporator can also be used to concentrate a solution by evaporating a solvent from a mixture and leaving behind a more concentrated solution.

Working Principle

The working principle of a vacuum evaporation concentrator is based on the principle of boiling point elevation. When a vacuum is applied to the solution, the boiling point of the solution increases. This allows the solvent to evaporate faster than it would at atmospheric pressure, resulting in a concentrated sample. The evaporation process can also be accelerated by adding heat to the solution.

Product Features

- The main equipment of the spherical concentrator is made of high-grade stainless steel, and the inside and outside are finely polished to prevent the material from sticking to the wall, not easy to scale, block, stick to the wall, and foam, and it is easy to clean;

- Adopt reduced pressure concentration, reduce the operating temperature, shorten the concentration time, effectively retain the effective ingredients in the material;

- The spherical concentrator is a jacket structure, the condenser is a tubular structure, and the cooler is a coil structure;

- According to process requirements, various extraction and concentration operations such as negative pressure and normal pressure can be realized, just switch the valve, which is easy to operate; The spherical concentrator adopts reduced pressure concentration operation, the evaporation temperature is low, and a stirrer can be installed to increase the evaporation speed. Prevent material adhesion, reduce foam formation, and increase the concentration of finished products;

- The spherical concentrator has a compact structure and covers a small area; Solvents are used in closed circulation in the equipment, which can reduce the investment by more than 50%, with small investment and high efficiency, effectively reducing environmental pollution, and meeting the requirements of GMP standards.

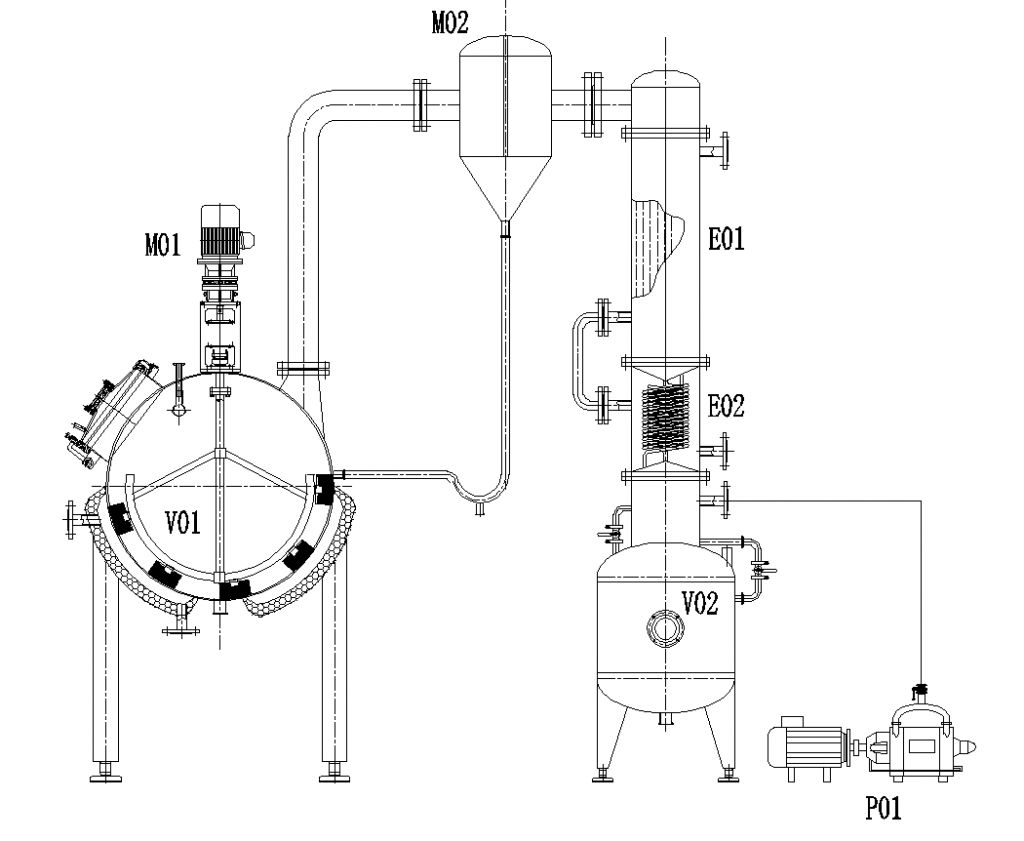

Product Structure

Spherical concentrator is composed of five parts: concentrator, vapor-liquid separator, condenser, cooler and receiving tank.

- The concentrator is spherical with interlayers, and the material in the spherical tank can be heated by an external heat source.

- The evaporation and concentration process is completed here.

- The vapor-liquid separator separates the material liquid carried by the steam, and the unvaporized material liquid returns to the concentrator to continue the conversion from liquid to gas.

- The condenser liquefies the gaseous solvent to achieve the purpose of solvent recovery.

- The cooler further lowers the temperature of the liquefied solvent to achieve full recovery of the solvent.

- The receiving tank collects and stores the liquefied solvent. In addition to these five main devices, there are also auxiliary equipment such as stirring motors and vacuum pumps.

M01—Stirring Motor

M02—Gas-liquid Separator E01—Tube Condenser

E02—Coil Cooler V01—Concentration Tank

V02—Coolant Collection Tank

P01—Water Ring Vacuum Pump

Operation Method

Open the vacuum port and the inlet valve to pump the liquid into the tank. After the liquid level in the tank reaches a certain height, close the inlet valve and slowly open the steam inlet valve. After the material in the tank is boiled for a few minutes, maintain the vapor pressure and vacuum at this time. The boiling material liquid is vaporized and enters the separator, and part of the material liquid that has not been vaporized is returned to the concentration tank. The gas is condensed and liquefied by the condenser and flows into the receiving tank for collection or transfer. After the concentration is over, close the vacuum port and steam port valve, open the vent valve, and the system will discharge after normal pressure.

Spherical Concentrator | |||||

| Model | LPSC-100 | LPSC-200 | LPSC-300 | LPSC-500 | LPSC-1000 |

| Volume(L) | 100 | 200 | 300 | 500 | 1000 |

| Evaporation capacity(L/H) | 15-20 | 20-50 | 50-100 | 100-150 | 200-300 |

| Heating area(m2) | 0.6 | 0.8 | 1.2 | 1.6 | 2.6 |

| Cooling area(m2) | 3 | 4 | 6 | 9 | 18 |

| Condensing area(m2) | 0.5 | 0.5 | 1 | 2 | 3 |

| Coolant collection tank (L) | 70 | 70 | 115 | 115 | 170 |

| Vacuum pump(KW) | 1.5 | 1.5 | 2.2 | 3 | 4 |

The parameters are for reference only. | |||||

Product Details

- Equipped with explosion-proof light, which is easy to observe the internal reaction.

- Equipped with explosion-proof motor with high safety factor.

- A coil-type cooler is added to the rear of the tubular condenser to increase the recovery rate.

- Unique mixing design and PTFE scraper material selection

Auxiliary Products

- Steam generator provides heat source.

- Cooling tower provides cold source.

- The liquid storage tank can be used for transfer and store.

Reviews

There are no reviews yet.