Description

Product Definition

The oil press refers to a kind of device that can, by means of external mechanical force, squeezes grease from oil through raising the temperature and activating oil molecules.

Product Classification

Oil presses can fall into household oil press, hydraulic oil press, screw oil press, new hydraulic oil press, high efficiency fine oil filter press and automatic oil press.

What we introduced now is screw oil press. Compared to other types of oil presses, a screw oil press has a high oil capacity, good cost performance and simple operation although the oil quality is not as good as that of other oil presses. (A hydraulic oil press only need a small driving force, which can be drove by both three-phase and household electricity. The oil is clear but the output is low. So a hydraulic oil press is more suitable for expressing high-end oil such as sesame oil and walnut oil.)

Expression Method

There are two methods for extracting edible oil from plants, which are chemical extraction and physical extraction. Normally they are also known as lixiviation method (chemical) and expressing method (physical).

With a long history, the expression method has a relatively simple process. After steaming and frying raw material, it can express oil from the material by means of mechanical method. The traditional expression method requires strenuous manual labour and the content of residual oil is quite high, wasting extremely valuable raw material. The modern expression method can complete industrial automatic operation, but it neither solve the problem that the content of residual oil is high.

There is cold press and hot press in terms of the pre-treatment of raw material. The cold press refers to the process where raw material, without drying, frying and steaming, is directly put into the oil press for extracting oil. The oil produced by cold press is more bright with a relatively light color, but it has a low oil yield and no rich, nice and mellow flavor. The hot press refers to the process where raw material is dried before expression to lower moisture in the material and enhance the activity and mobility of oil molecules so that it can improve the oil yield and ensure the rich flavor of oil. But the oil has a darker and blacker color due to its chemical compositions are destroyed.

Press Technology

- Conventional production process: raw material — steam and fry — press — crude oil pressed by machine

- Special oil production process: oil seeds — fry oil seeds — press — filter — perfumed oils and fats

- Special oil material production process: oil seeds — cold press for whole oil seeds — filter — oils and fats produced by cold press

The process that expresses oil from raw material:

When the raw material comes into the oil press, it will rotate along with the barrel and pressure will increase. With the extrusion of oils and fats, the seeds are constantly squeezed, and the pressure generated by material particles that are in direct contact with each other can cause the deformation of seeds and particularly the adhesion at the broken place of oil film. Hence, the material is not loose anymore but can be shaped after being squeezed out of the barrel, known as oil cake. Under the dual action of temperature and pressure, the protein continuous to be spoiled, influencing the plasticity of the material. In conclusion, only the proper denaturation of protein can ensure the best extraction effect.

Product Advantages

No chemical additive is added in the production process by adopting this device.

- Simple operation with one button;

- Large power, low heating and high efficiency;

- High oil yield and low pressing cost;

- Practical, more selections of raw materials and simple and convenient procurement;

- High quality oil with rich nutrition;

- Overall stainless steel appearance is convenient for cleaning;

- Barrels and bars are simple to disassemble and convenient to clean.

Product Features

1.The natural press, learning from conventional ways, adopts physical method to express oil.

2.Physical expression at low temperature.

The counter-acting force of the surface bearing allows the machine to press oil more quickly.

The material can be heated uniformly, preventing blockage and sticking.

3.The high power copper core motor has a low heating.

Hardened Gear / Low-Noise Bearing / Copper Coil

4.The dual air-cooled configurations with dual heat dissipation can easily achieve the continuous operation.

100mm Air Inlet / Ten-Bladed Fan / Low-Noise Bearing

Product Parameters

| Model | Total Power (W) | Rotating Speed (rpm) | Net Weight (kg) | Gross Weight (kg) | Processing Capacity (kg/day) | Price (RMB) | Material |

| LFHOP-501 | 350 | 80 | 10.5 | 13.5 | 30 | 1280 | Shell: SUS201 Barrel: SUS304 Press Rod: SUS420 |

| LFHOP-509 | 600 | 80 | 11 | 13 | 35 | 1680 | |

| LFHOP-899 | 720 | 80 | 12.5 | 16 | 50 | 1880 | |

| LFHOP-T11 | 1400 | 80 | 46 | 50 | 100 | 4800 | |

| LFHOP-T15 | 3000 | 80 | 53 | 70 | 180 | 6800 |

Attached Table: Oil Yield

| Raw Material | Oil Yield | Oil Content |

| Peanut | 38~45% | 35~50% |

| Sesame | 42~55% | 55~58% |

| Rapeseed | 28~45% | 35~48% |

| Sunflower Seed | 40~45% | 50~55% |

(Note: Prevent tiny pieces of sand from coming into rapeseed, sesame and flaxseed in order to avoid the wear of the press rod and barrels.)

Operation Procedures

- Plug in the power cord, connect to the power supply of 220V and use the single phase three-hole socket. The socket should be well-grounded.

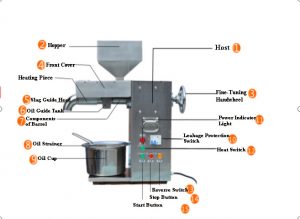

- Turn on the power switch (⑩). When the power indicator light (⑪) is on, there is electricity.

- Turn on the heat switch (⑫), and heat about 10 minutes. (The raw materials can be baked and stir-fried during the heating process.) Don’t turn off the heat switch due to the temperature can be controlled automatically.

- Stir-fry raw material: pour raw material into the frying oven or iron pot. It should be medium-done at least. The more ripe the oil is, the more fragrant the oil is. Any material should be stir-fried now, otherwise the effect is not good.

- Pour the cooked material into the hopper (②). Rotate the fine-tuning handwheel (③) in the clockwise direction until it can’t move and then turn back for one circle. Adjust the fine-tuning handwheel again based on the humidity of slag during the process of pressing oil until the slag is dry and clear. Because it’s hard to rotate the handwheel when there is material in the barrel, put a small amount of raw material for debugging. Reduce the gap between the barrel and press rod properly in the clockwise direction if the slag is relatively thick and there is residual oil. Adjust it in the anticlockwise direction if the gap is too small. The gap shouldn’t be too small, which will cause the wear of the barrel.

- Press the start button (⑮) to start pressing oil. If there is any abnormal condition, press the stop button (⑭). If there is any impurity entering the barrel, stop pressing oil immediately and press the reverse button (⑬). Re-start pressing oil after cleaning impurities.

- After the oil is pressed, run it idle for three to five minutes, and then press the motor stop button (⑭). Turn on the heat switch (⑫) ten minutes before the end of oil pressing.

Materials that can’t be pressed: corn, olive, rice, pork, and all materials containing no oil.

Disassembling Method

- Well place the oil that is freshly pressed. Remove the hopper and turn up the front cover.

- Remove the lock screws of the barrel.

- Take down the barrel.

- Take out the press rod.

- After cleaning the barrel and the press rod, dry them for use or assemble them. (The rust will occur when water stays for more than eight hours.)

Machine Maintenance

Note: After using it for about a half of year, it is required to inject lubricating oil into its gear box for extending service life.

- Oil Type: 320# Worm Gear Oil

- Oil Filling Capacity: 100 ~ 150 ML/Every Time

- Oil Filling Cycle: above 1500 hours of actual use (about half a year)

- Oil Filling Method: it is showed as following pictures

Precautions for Installation and Use

- The voltage used for this machine should be 220V. Please use the single phase three-hole socket that is well-grounded. It should be ensured that the power plug is inserted securely when connecting to the power supply. Don’t plug out the power plug during the normal operation. Check the power cord regularly and don’t use the machine when the power cord is damaged. Try not to share sockets with other electrical appliances or use long cords.

- The machine can be only used by adults, keeping it away from kids and pets during the operation. People lack of using knowledge should use the equipment under the guidance of professional personnel. Don’t use fingers to fiddle with raw materials in the feed port.

- The working parts of the machine have a relatively high temperature during the work. Don’t touch them with your hands to avoid scald. It is required to wear gloves to clean the machine or clean it after the heat comes down due to the barrel and the press rod, especially the pre-heating parts, have a relatively high temperature.

- Keep it away from high temperature, high humidity and open fire, and avoid long hours of direct sunlight. Place it on a smooth desktop that can completely bear its weight, which should be solid wood desktop or marble slab as far as possible. If it is placed on a hollow desktop, there will be much more noise because of vibration. It is better to pad a soft cloth over it. Keep horizontal and don’t tap.

- Don’t use water to flush the host, which should be wiped by dry cloth. After cleaning the barrel and the press rod, blow or wipe them for drying and then re-assemble them. The power plug must be plugged out when cleaning components or using wet cloth to wipe the host.

- After finishing the oil pressing, make it rotate reversely for ten seconds if no slag is discharged. It can be extended to about one minutes when necessary (when the raw material is damp). The press rod is possible to be hardly taken out from the barrel if this step is ignored.

- If it isn’t used for a long time, keep it in a dry ventilated place to prevent the motor from humidity.

FAQ

- What if impurities come into the feed port?

A: Stop the machine immediately. Start the reverse motor to get impurities and raw material back and then dismount the barrel. Clean up before continuing to work.

- What if the press rod can not be taken out from the barrel?

A: Install the machine again, and it can be taken out after running the machine idle for five minutes.

- What if the power supply is suddenly cut off for more than 30 minutes during the operation?

A: Turn off the power supply timely, plug out the power plug, and remove the visible raw materials from the feed port. When there is electricity, heat it up for 20 minutes before starting the motor. Normally it can go on working. If it still can’t work after heating up, the barrel and the press rod should be dismounted for cleaning and then re-assemble them for starting up.

- Is the pressing method same for different raw materials?

A: No, there are different pressing methods for various raw materials.

For example:

- Peanut: stir-fry peanuts until they are well-done and can be flattened by hand, which is more suitable for pressing oil. Too crisp peanuts will be ground into powder, not easy to produce oil. If you want to obtain strong aromatic peanut oil, peanuts should be stir-fried until they are crispy. And then add 5% of clear water to stir-fry them until there is no obvious water on the surface. The peanuts can be pressed now. If it is allowed, put peanuts that has been stir-fried to crispy into a stream pot for steaming a while. Then the oil pressed will be quite mellow and fragrant.

- Sesame: 1. this machine isn’t suitable for pressing puffed cooked sesame. Being fragrant and crisp, puffed cooked sesame serves as the raw material for making sesame paste. The material for pressing oil must be soft and can be pressed into slices, so the puffed cooked sesame can only be made into paste but can’t produce oil. This machine can’t be compared to large industrial oil presses due to they have different structural designs and principles. 2. The peeling sesame is mainly used for making cakes and pastries. Without the epidermin, the peeling sesame will hinder the production process and lead to wet slag if it is used for pressing oil. The black sesame and white sesame with skin freshly stir-fried are the first choice to press sesame oil.

- More rigid material: soybean, tea seed, hemp seed, walnut, rapeseed, sunflower seed. Soft their surface by stir-frying before pressing oil.

- Materials whose nutrient components will be destroyed by heating can be directly pressed, such as flax seed and perilla seed.

- How to deal with oil residue after pressing?

A: The oil residue can be regarded as fat-free nuts, which can be made into various food, or can serve as organic fertilizer used for planting flowers and vegetables.

Turn Oil Residue into Treasure

The oil residue is a fat-free nut, which can be made into various food, or can be used to plant flowers and vegetables, and feed fishes.

Grilled Eel Over Rice

[Ingredients] Dried apricot, cucumber, white sesame dregs, dried pepper, sugar, salt, white sesame oil.

[Making] 1. Clean up the eel after removing its internal organs. Cut eel meat into long strips, and steam about 10 minutes before taking out.

- Pour oil, sugar, sweet red wine into a pot, and heat them to make the sauce.

- Place the tin foil on the baking tray and spread the sauce on the tin foil. Bake for another 7 minutes. Finally sprinkle with white sesame dregs.

Peanut Dregs Pancake

[Ingredients] Flour, edible oil, seasoning powder, peanut residue.

[Making] 1. Add appropriate amount of flour into proper amount of peanut residue.

- Add appropriate amount of water to make a dough. Leave it for ten minutes.

- Knead the dough well. The thinner the layer, the more layers.

- Sprinkle the dough with seasoning powder and edibleoil, and fold it into a fan shape.

- Fold the folded dough in half to squeeze the cake.

- Put oil in a frying pan. Heat the oil in the frying pan and fry both sides until brown. It is edible now.

Peanut Dregs Steamed Corn Bread

[Ingredients] Corn flour, peanut dregs, edible oil and sugar.

[Making] 1. Put appropriate amount of peanut dregs into the dish, pour into a bowl of corn flour and put into sugar.

- Put in the baking soda and stir well. Leave it for 20 minutes.

- Make balls with hands. Boil water, and then put in steamed corn breads to steam for 15 minutes. Steam for two minutes after turning off the fire. Open the lid to take out the steamed corn breads.

Braised Pork Ribs with Pumpkin Dregs

[Ingredients] Ribs, pumpkin, cooking wine, light soy sauce, salt, minced garlic, pumpkin dregs, sugar and pepper.

[Making] 1. Put garlic, light soy sauce, salt, chicken powder, cooking wine and salt into the ribs.

- Sprinkle in corn flour and stir evenly. Leave it for about half an hour.

- After water is boiled, sprinkle pumpkin dregs and steam for 50 minutes. Then sprinkle peppers when it is done.

Attachment List

Packing and Shipping

Reviews

There are no reviews yet.