Description

A 50L single-effect falling film evaporator can be used to evaporate extract liquid under reduced pressure or vacuum condition so that ethanol and liquid material can be separated, condensed and recycled. The single-effect falling film evaporator used for evaporating ethanol solution is different from the one used for evaporating general aqueous solution. The ethanol has a relatively low boiling point, which is volatile. It’s easy to evaporate ethanol solution under reduced pressure or vacuum condition. So it’s relatively difficult to condense and recycle ethanol steam with a smaller evaporation area. Thus the heat exchange area of the condenser is larger. To obtain a better cooling effect, the two-stage or several-stage method is frequently used for cooling and recycling, which also varies from the evaporation of general aqueous solution.

Working Principle

The liquid material is distributed evenly into each falling film tube by distributors and flows downward along the tube wall in the form of liquid film. The liquid material is evaporated during the process of flowing downward under actions of gravity and secondary steam flow. The liquid material and secondary steam are separated basically after reaching the lower part of falling film tubes and separated completely after reaching the separation chamber.

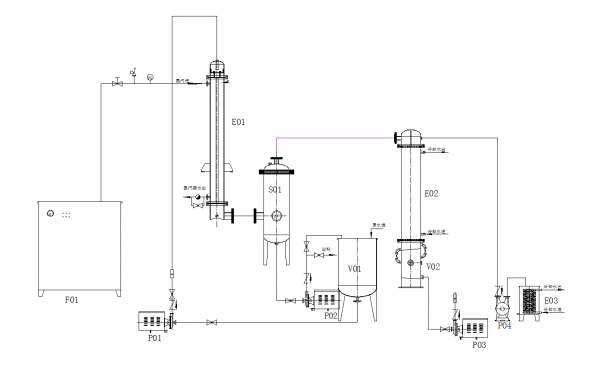

Structure Diagram

F01——Steam Generator S01——Evaporation and Separation Chamber

E01——Tubular Heater E02——Tubular Condenser

E03——Vacuum Pump Cooler V01——Intermediate Tank

V02——Ethanol Receiving Tank P01——Feed Pump

P02——Discharge Pump for Concentrated Liquid P03——Discharge Pump for Ethanol

P04——Water Circulating Vacuum Pump

Working Process

Feed (V01) —— Evaporation (E01) —— Separation (S01) —— Condensation (E02) ——Storage Tank (V02)

Product Parameters

| Product Model | FFE-50 |

| Evaporation Rate (L/H) | 50 |

| Heating Area (㎡) | 3 |

| Condensing Area (㎡) | 5 |

| Vacuum Degree (Mpa) | -0.095 |

| Steam Volume of Steam Generator (KG/H) | 50 |

| Power of Steam Generator (KW) | 36 |

| Power of Feed Pump (KW) | 0.55 |

| Power of Discharge Pump (Concentrated Liquid, KW) | 0.55 |

| Power of Discharge Pump (Ethanol, KW) | 0.55 |

| Power of Water Circulating Vacuum Pump (KW) | 0.81 |

| Power Supply | 220V/60Hz Three Phase, other can be customized. |

Product Details

1. The high quality steam generator has a high efficiency and long service life.

2. The high-quality steam trap can prevent steam leakage efficiently.

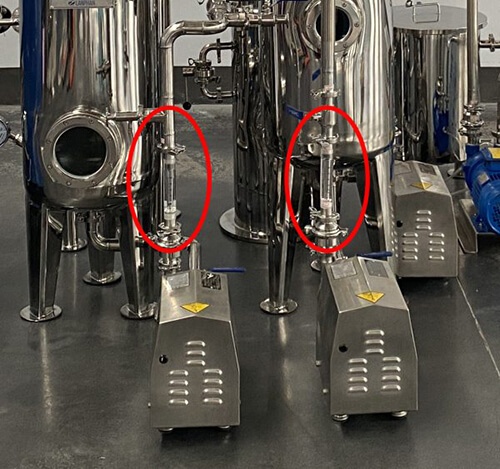

3. The sampling port is convenient to take samples at any time for observing the concentration of concentrated liquid.

4. The flowmeter is equipped for feeding and discharging, which is convenient to learn the dynamic condition of liquid material.

Product Advantages

1.Low heating temperature;

2.Rapid Evaporation Rate;

3.Short retention time of liquid material;

4.Continuous feeding and discharging;

5.Suitable for heat-sensitive material;

6.Low energy consumption.

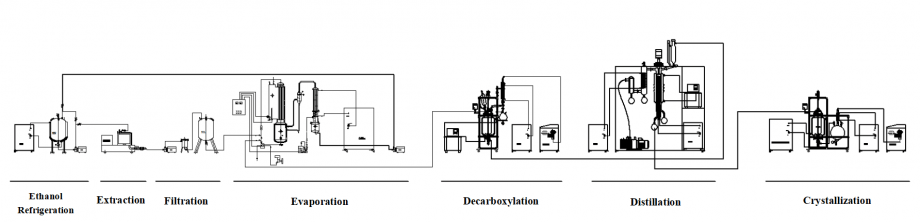

One-Stop Solution Process

Product Application

A single-effect falling film evaporator is widely used in food, dairy, chemical, pharmaceutical, biological engineering, environmental engineering and deep processing of corn. For example, it is applicable for the evaporation and concentration of aqueous solution, organic solvent solution, fruit and vegetable juice, milk, egg product, vitamin C, collagen, infusion of tea, sodium glutamate and other liquid materials. It is especially suitable for the evaporation and concentration of heat-sensitive materials, because the beneficial elements can be protected to the greatest extent during the heating and evaporation of materials.

Pre-Sale Service

- Provide 24-hour technical consultation and reply;

- Provide professional quotation information;

- Provide detailed product performance specification;

- According to product’s using condition, technicians will offer rationalization proposals to assist clients to select proper product types;

- Provide other corollary equipment according to client requirements.

In-Sale Service

- With supervision from the source of products, the qualified rate of raw materials entering the factory can reach 100%;

- Whole manufacturing process are in strict accordance with promised procedure requirements, product qualified rate can reach100%;

- Provide product’s inspection record of key junctures to customers;

- Provide production schedule photos to customers at regular intervals;

- Package and transport of products are in strictaccordance with the export standard;

- Provide transportation schedule information to clients timely.

After-Sale Service

- Provide targeted installation video;

- Under the premise of correct installation, normal maintenance and using, we guarantee one-year warranty period;

- When warranty period has expired, our sold products enjoys lifetime guarantee repair, we only charge cost price for changing product’s standard component and sealing component;

- During installation and adjustment period, our after-sale service staff will communicate with customers frequently to know product’s running state in time. Assist customers to install and adjust products until customers are satisfied;

- If product has malfunction during operation period, we’ll offer you satisfied answer in time. We’ll reply you within 1 hour and provide solution or send staff to spot within 24 hours after receiving maintenance notification;

- Lifelong free technical support. Conduct satisfaction survey and inquiry equipment running condition to clients by telephone or e-mail semiannually from the first day of equipment running, put on records of acquired information;

- Provide assistance in solving problems such as equipment damage in the transport.

Reviews

There are no reviews yet.