Description

Product Description

LFFM – II filling machine is improved and innovated based on our company’s filling machine series and referring to foreign filling machine technology. It has a much simpler and more reasonable structure, higher accuracy and easier operation. Working in an uncharged state, it possesses both the security and humanization, greatly according with the modern enterprises’ need. It is suitable for pharmaceutical, daily chemical, food, pesticide and special industries, serving as an ideal equipment to fill ordinary fluids and high viscosity fluids.

It is a semi-automatic or fully automatic piston filling machine, with a reasonable structure, small and exquisite model, and simple operation. All pneumatic components adopt the pneumatic elements of FESTO in Germany or AirTac in Taiwan. It works by using the air cylinder to drive the piston for extracting material, using one-way valve to control the material flow and using the magnetic reed switch to control the stroke of the air cylinder for adjusting the filling volume. The parts in contact with materials is made of stainless steel 304 and the shell is made of stainless steel 201, conforming to GMP requirements and having a higher filling accuracy.

Working Principle

The filling machine is a semi-automatic piston filling machine. A piston is driven by the cylinder to extract and eject the material, the one-way valve is used to control the flow direction of the material, and the reed switch is used to control the stroke of the cylinder to adjust the filling volume.

Product Advantages

- The parts in contact with the materials is made of stainless steel 304 and the shell is made of stainless steel 201. All can also be made of stainless steel 316 as required by customers.

- All pneumatic components adopt the pneumatic elements of FESTO in Germany or AirTac in Taiwan, with a stable performance and high filling accuracy.

- The seals adopt silicone rubber (wear resistance, high temperature resistance, acid and alkali resistance, corrosion resistance) and fluorine rubber (wear resistance, strong acid and alkali resistance, strong corrosion resistance).

- The fully pneumatic device has a better security.

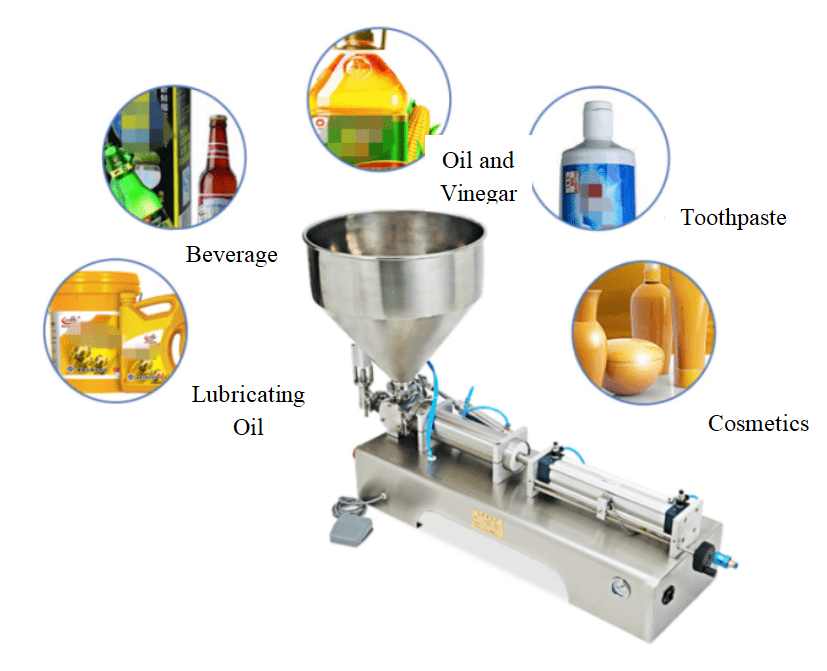

Application Scenario

The products is widely used in beverage, oil and vinegar, lubricating oil, toothpaste and cosmetics industry.

- Liquid: beverage, fruit juice, fruit-acid drink, sesame oil, wine, soy sauce, vinegar, etc.

- Paste: It is an ideal filling machine for pesticide, pharmaceutical (gynecological drugs, Compound Dexamethasone Acetate, Erythromycin Ointment, anti-frost cream, etc.), daily chemical (toothpaste, shoe polish, moisturizer, lipstick, etc.), food (sesame sauce, sweet flour sauce, tomato sauce, cream, etc.), chemical (glass adhesive, sealant, white latex, etc.), lubricating oil and special industries.

Product Parameters

| Filling Range | 5-100ml | 20-200ml | 30-500ml | 100-1000ml | 500-2500ml | 1000-5000ml |

| Air Pressure | 0.4~0.9Mpa | |||||

| Gas Consumption | 0.1m³/min | |||||

| Handling Capacity | 1-25 bottles/min | |||||

| Accuracy | ±0.5% | |||||

| Packing Size of Single Head | 80*30*30 | 100*40*40 | 120*40*40 | 125*43*43 | ||

| Weight of Single Head | 25 | 30 | 40 | 50 | ||

| Packing Size of Double Heads | 80*60*30 | 100*80*35 | 120*80*40 | 125*95*43 | ||

| Weight of Double Heads | 40 | 50 | 65 | 70 | ||

Product Price (RMB)

1.Semi-Automatic (electric-pneumatic hybrid)

| Filling Range | 5-100ml | 20-200ml | 30-500ml | 100-1000ml | 500-2500ml | 1000-5000ml |

| Single Head for Liquid | 1500 | 1850 | 2200 | 2300 | 4200 | 4900 |

| Double Heads for Liquid | 2500 | 3400 | 3600 | 3800 | 5600 | 7500 |

| Single Head for Paste | 2300 | 2600 | 3000 | 3200 | 5300 | 7300 |

| Double Heads for Paste | 4100 | 4500 | 5000 | 5200 | 7300 | 9300 |

2.Fully Automatic (pneumatic)

| Filling Range | 5-100ml | 20-200ml | 30-500ml | 100-1000ml | 500-2500ml | 1000-5000ml |

| Single Head for Liquid | 2100 | 2450 | 2800 | 2900 | 4800 | 5500 |

| Double Heads for Liquid | 3100 | 4000 | 4200 | 4400 | 6200 | 8100 |

| Single Head for Paste | 2900 | 3200 | 3600 | 3800 | 5900 | 7900 |

| Double Heads for Paste | 4700 | 5100 | 5600 | 5800 | 7900 | 9900 |

Notes:

- The above quotation excludes wooden cases. Each packaging case is from 400RMB to 500RMB.

- The voltage of semi-automatic product is 220V/50HZ. If you have any need for other voltage, the delivery time is from 10 to 15 days.

- The paste filling machine is allowed to be equipped with a hopper. The package size is 450*450*550 and the weight is 10kg.

Product Details

Stainless Steel Machine Body

The thickened stainless steel is resistant to corrosion and tear, making the machine can also be used in hostile environment.

High Quality Buckle

The high quality stainless steel buckle is firm, durable, and easy to disassemble.

Filling Adjustment Rocker

It’s a manual handle for adjusting filling volume within the range of regulation, simple to operate.

Removable Buckle, One-Button Cleaning, No Screws Required

It can fill food or products with various colors and flavors. It’s convenient to clean, saving both time and energy.

High Accuracy Pressure Gauges

The high accuracy pressure gauge has a stable performance.

Air Port

It’s convenient and practical for operation with a high and stable working efficiency.

Emergency Stop

The emergency stop button can stop the machine.

Inching / Automatic Control

Provide more diversified choices to satisfy customers’ needs.

Instructions for Use

Use, Maintenance and Installation

- It belongs to a semi-automatic or automatic machine, requiring that bottles, bottle mats and bottle caps should be matched with each other.

- Test the machine with water before starting up to observe if its rotation has any abnormal phenomenon. The material can be fed into operation after being proved normal.

- It’s forbidden to dismount components with too large tools or excessive power in order to avoid damaging components or influencing machine performance.

- When the machine is adjusted, tighten the loose screws before starting up.

- Keep the machine clean. It is forbidden to have oil stains, physic liquor or bits of glass on it so as to avoid machine damage. The following must be done:

- Remove physic liquor or bits of glass in time during the production.

- Before handing over to the next shift, clean the machine surface and each component once, and add the clean lubricating oil into each moving part.

- Thoroughly clean the machine every week, especially dead corners. Or blow it with compressed air.

Disinfection and Cleaning

- Loosen the upper and lower fastening screws and remove the liquid injection components to do the overall disinfection and cleaning.

- Put liquid inlet pipes in the cleaning fluid, and start the machine for cleaning.

- The 500ml model may have errors in actual filling, so the measuring cylinder should be accurate before the formal filling.

- Needle tube for filling machine, standard 5ml or 10ml syringe for type 10, 20ml glass filler for type 20, and 100ml glass filler for type 100.

Installation Precautions

- After the machine is unpacked, first check whether the random technical information is complete and whether the machine is damaged during transportation, so as to solve it in time.

- Install and adjust the feeding component and the discharging component according to the outline diagram in this manual.

- Add new lubricating oil to each lubrication point.

- Rotate the machine with the crank handle to check whether the machine is running in the correct direction (counterclockwise when facing the motor shaft), and the machine must be grounded.

Related Products

1.Air pump

2.Cap screwing machine

Recommended Products

1.Pure water and beverage production line

2.Washing machine with dryer

FAQ

- What filling machines do you have?

A: Fully pneumatic filling machine and electric-pneumatic hybrid filling machine.

- What products should be matched with it?

A: It need to be matched with an air compressor. (Customers can do it by themselves, and the recommended parameter is 1KW and 40L.) The products leave our factory with 1.5m high pressure hose (φ20).

- Which industries can the products be used in?

A: The parts in contact with the materials is made of stainless steel 304 and the shell is made of stainless steel 201. All can also be made of stainless steel 316 as required by customers. The products is widely used in beverage, oil and vinegar, lubricating oil, toothpaste and cosmetics industry.

- What kind of technical support can you provide?

A: The product are delivered as a whole, which can be used without assembly.

- Does the product occupy a large land? Is it easy to operate?

A: The product in our company is an integrated equipment, occupying a small land, saving cost and easy to operate. The manual handle is used to regulate the filling volume, easy and simple to operate.

- What kind of payment terms do you accept?

A: Normally we accept TT, Paypal, Western Union, Alibaba International Alipay and L/C. The exact term will be discussed in the deal.

- How do you pack the products?

A: Non-fumigation wooden boxes are used for packaging.

Customer Service

Pre-Sale Service

- According to product’s using condition, technicians will offer rationalization proposals to assist clients to select proper product types;

- Provide detailed product performance description;

- Provide professional quotation information;

- Provide 24-hour technical consultation.

In-Sale Service

- With supervision from the source of products, the qualified rate of raw materials entering the factory can reach 100%;

- Whole manufacturing process are in strict accordance with promised procedure requirements, product qualified rate can reach 100%;

- Provide product’s inspection record of key junctures to customers;

- Provide production schedule photos to customers at regular intervals;

- Package and transport of products are in strict accordance with the export standard.

After-Sale Service

- Under the premise of correct installation, normal maintenance and using, we guarantee one-year warranty period;

- When warranty period has expired, our sold products enjoys lifetime guarantee repair, we only charge cost price for changing product’s standard component and sealing component;

- During installation and adjustment period, our after-sale service staff will communicate with customers frequently to know product’s running state in time. Assist customers to install and adjust products until customers are satisfied.

Packing and Shipping

Reviews

There are no reviews yet.