Description

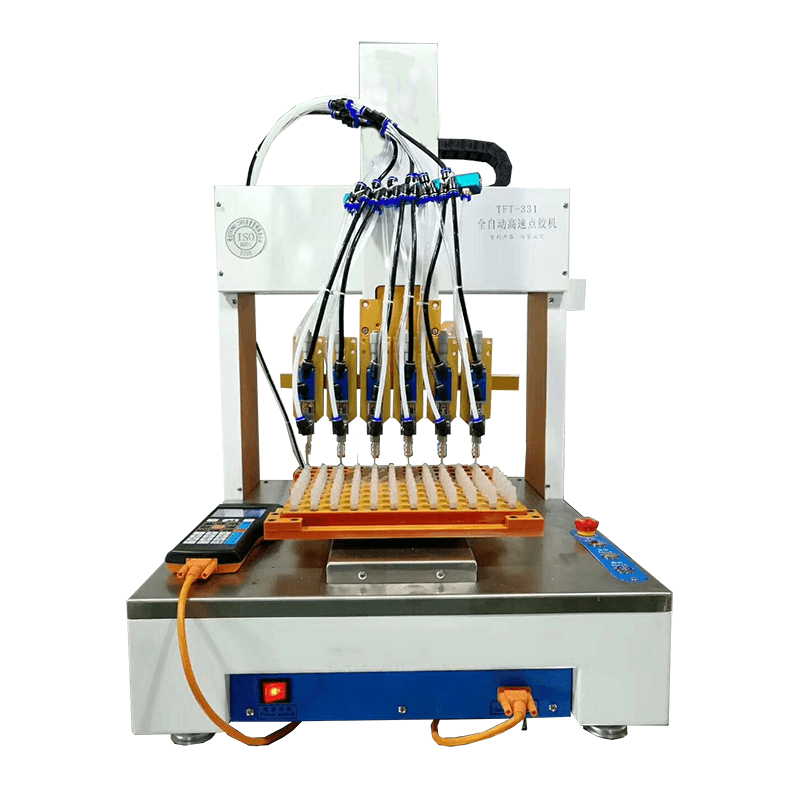

Product Description

The oiling machine is a kind of glue dispenser. This machine is suitable for a variety of connector plug-in tests. It adopts embedded microcomputer measurement and control technology. It can display the insertion force, pull-out force and real-time force value at the same time, and has the number of setting, the speed stroke is adjustable, and can display the speed value, automatic zero return, unit conversion, etc. are displayed. The dynamic design of the rotating eccentric wheel makes the test speed and the test stroke not related. Long and short stroke connectors are also tested quickly.

Product Features

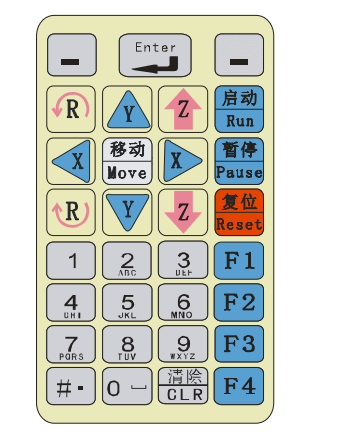

- The handheld box uses a 320*240 high-resolution color screen and a full English operation interface, which is easy to learn and use.

- It has graphic elements such as drawing points, straight lines, polylines, three-dimensional arcs (space arcs), circles, racetracks, rectangles, coatings, automatic rounding, irregular three-dimensional splines, etc.; It has rich manual teaching function and graphics preview function.

- With conditional jump function, and double MARK point rotation and needle alignment function.

- With skip selection function, multiple discontinuous instructions can be selected at the same time.

- With command movement function, the edited command can be moved to the target position.

- It has a breakpoint execution function, which can start execution from a specified point.

- It has the functions of area array copy, offset operation, batch editing, single step operation, I/O input and output.

- With functions such as automatic execution, automatic reset, output setting, processing time timer, etc.

- There are four different wire drawing process options, which can solve process problems such as wire drawing.

- Support DXF and PLT file import, automatic path optimization function.

- After editing the action parameters, download the action parameters to the controller through the serial port, and then you can run it offline and independently. The action parameters can also be saved in the handheld box for easy recall; and can copy and save graphics between devices.

- The handheld box can store hundreds of processing files, and each file can support 8000 commands, which can be called up when in use.

- The hardware has 4 gun channel controls, 4 general outputs, 8 inputs, and 12 high-speed pulse outputs; the accuracy of the control dispensing time is 1ms.

- Each action command has independent glue opening delay, glue closing delay, gun withdrawal height, and independent glue closing function in advance. The flexible batch modification function can improve editing efficiency and solve the problem of glue stacking.

- Support batch modification of parameters by type classification.

Product Application

The oiling machine is suitable for the precise filling of most fluids, and it can also be used for the filling of oils, colloids and other fluids with high viscosity and poor fluidity.

Product Parameters

| Model | TFT-331 | TFT-441 | TFT-551 | TFT-661 |

| Scope of oil X/Y/Z(mm) | 300/300/100 mm | 400/400/100 mm | 500/500/100 mm | 600/600/100 mm |

| Number of thread | 1、2、3 | 1、2、3、4 | 1、2、3、4、5 | 1、2、3、4、5、6 |

| Load | Y/Z:5KG/3KG | |||

| Movement Speed | X&Y/Z(mm/sec):500/400 | |||

| Repeat precision | ±0.05mm | |||

| Overall dimensions | 537×560×820 mm | 637×660×820 mm | 737×760×820 mm | 537×560×820 mm |

| Machine weight | ≈70KG | ≈80KG | ≈90KG | ≈100KG |

| Program recording mode | 100 groups, 4000 dots per group (support U disk copy) | |||

| Display Mode | Teaching box LCD(320×240) | |||

| Motor System | High speed closed loop motor | |||

| Operation Mode | Point to point/continuous line segment | |||

| Drive Mode | Synchronous belt + precision linear guide rail | |||

| Edit mode | Teaching box/PC | |||

| 1/0 signal | 4 Inputs/4 Outputs | |||

| External space interface | RS232 | |||

| Input power | AC220V | |||

| Temperature of working environment | 5~40℃ | |||

| Humidity of working environment | 20~90% No condensation | |||

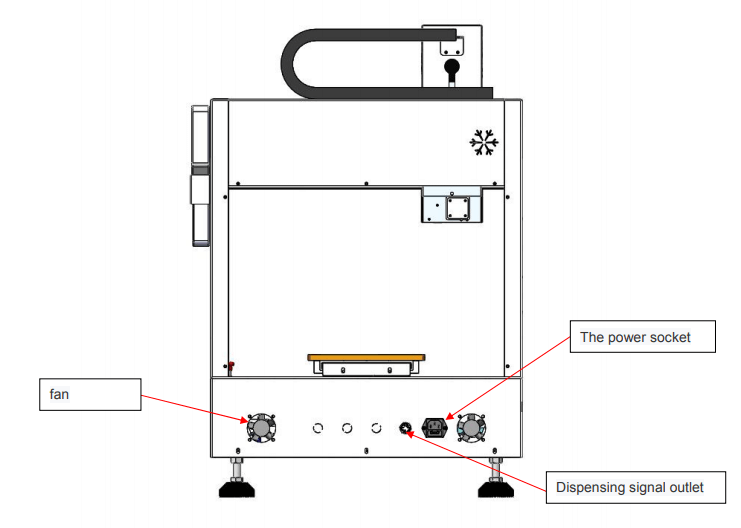

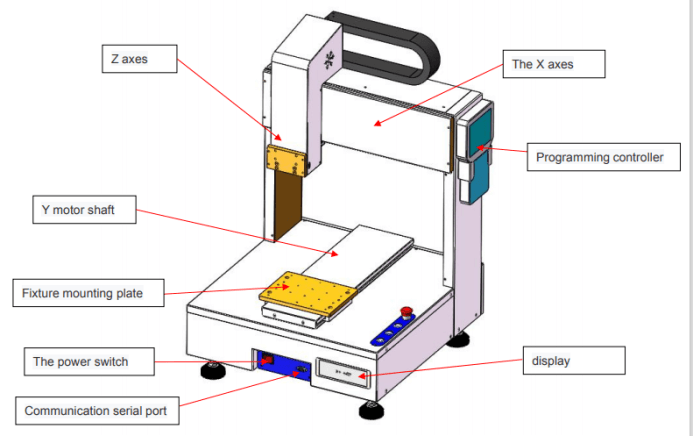

Product Details

- Hold the control box to accurately control the equipment stroke, operation mode, etc.; (please read the instructions carefully before use)

control box

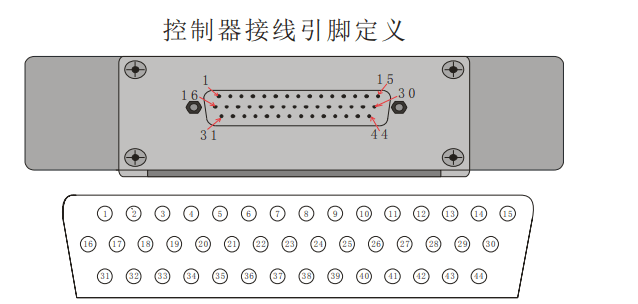

- The controller pins are clearly defined, and the wiring connection is clear and clear; (for details, please refer to the instructions for use)

controller pins

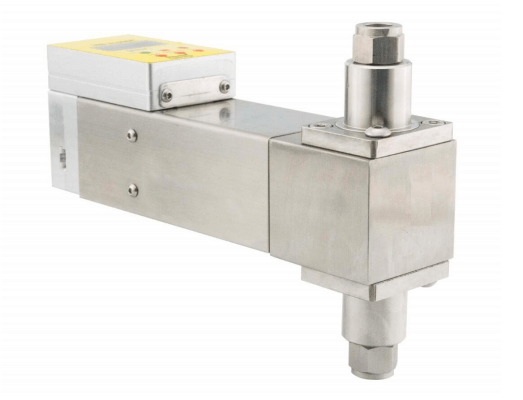

- DLC series precision metering pumps ensure the accuracy of the filling volume;

pump

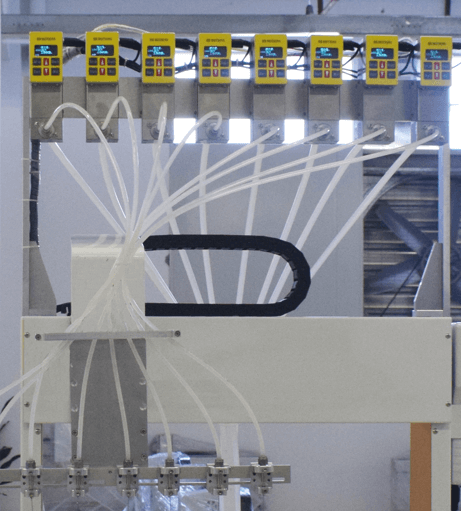

- Each oil outlet can be individually controlled, which can meet a variety of complex working conditions and achieve differentiated oil injection.

oiling outlet

Matters Needing Attention

- Equipment precautions

- Check whether the controller is intact;

- Check whether the DB44 pin socket is complete;

- After connecting the hardware according to the wiring diagram, check that the power supply voltage is not higher than 24V before powering on;

- After power-on, the device will first perform a reset action; the sequence of actions is as follows:

① The Z axis should move to the origin direction, if the moving direction is reversed (if it is a stepping system, swap any group of A, A- or B, B- in the motor line, if it is a servo system, you need to change the direction of the servo drive) , When the Z-axis origin switch is sensed, the Z-axis stops.

② The X and Y axes start to move at the same time, and the moving direction should move to the origin direction. If the direction is reversed (the same processing as when the Z axis is reversed), when one of the axes senses the origin switch, the corresponding axis will stop moving.

③When all the axes sense the sensors, the reset action is completed.

- Use the handheld box to set the origin of the device. Method: In the menu “Options” -> “Equipment Origin”, enter the “Equipment Origin Position” dialog box, and set according to the actual origin position of the device. This parameter is saved in the handheld box. At this time, the equipment installation work is basically completed.

The actual test also needs to be connected to the gas system for comprehensive debugging.

- Precautionsfor metering pumps

- When installing a metering pump, the liquid inlet should be on the bottom and the liquid outlet should be on the top. The pump head should be installed at an angle of 15~20 degrees upwards as far as possible to facilitate better discharge of air bubbles in the pump cavity;

- When using a metering pump to infuse liquids that are easy to crystallize or solidify, clean them in time after the work is completed to prevent the plunger or the one-way valve at the entrance and exit from jamming;

- The best effect is when the injection volume is 30% to 100% of the metering pump range;

- Regularly replace the wearable parts such as the sealing ring to obtain the best injection accuracy;

- Try to avoid running the metering pump without load when there is no liquid;

- DLC series pumps are not suitable for filling liquids with particles. If you want to inject liquids with particles, please use DRV series metering pumps;

- Please disconnect the power if you do not use it for a long time after work;

- If the touch screen of the shared device is used, the communication line needs to be twisted-pair shielded wire;

- When the metering pump is connected to the production line equipment, an isolation transformer should be equipped to prevent the electrical part of the metering pump from being affected by the power supply of high-power electrical appliances.

Common Problems and Troubleshooting

| Common Problems | Troubleshooting |

| The system does not reset | a) Check whether the power supply is normal; b) Check whether the drive is normal; c) Check whether the sensor status is normal; |

| Communication is not normal | a) Check whether the serial port cable is damaged; b) Check whether the device has completed the reset action; |

| Device can’t start | a) First, check whether the output has been completed, and then check it after connecting the handheld box. If the output has been completed, reset the output to zero; b) Check whether the start button is normal, you can use the handheld box to control the start of the device to eliminate this fault; c) If the handheld box cannot be started, use the handheld box to upload instructions from the controller to check whether there is an action command in the controller; d) Check whether the device is authorized. When the handheld box is connected and the “Start” button is pressed, a registration dialog box pops up on the screen, indicating that the device is not authorized to use; |

Pre-Sale Service

- Provide 24-hour technical consultation and reply;

- Provide professional quotation information;

- Provide detailed product performance specification;

- According to product’s using condition, technicians will offer rationalization proposals to assist clients to select proper product types;

- Provide other corollary equipment according to client requirements.

In-Sale Service

- With supervision from the source of products, the qualified rate of raw materials entering the factory can reach 100%;

- Whole manufacturing process are in strict accordance with promised procedure requirements, product qualified rate can reach 100%;

- Provide product’s inspection record of key junctures to customers;

- Provide production schedule photos to customers at regular intervals;

- Package and transport of products are in strict accordance with the export standard;

- Provide transportation schedule information to clients timely.

After-Sale Service

- Provide targeted installation video;

- Under the premise of correct installation, normal maintenance and using, we guarantee one-year warranty period;

- When warranty period has expired, our sold products enjoys lifetime guarantee repair, we only charge cost price for changing product’s standard component and sealing component;

- During installation and adjustment period, our after-sale service staff will communicate with customers frequently to know product’s running state in time. Assist customers to install and adjust products until customers are satisfied;

- If product has malfunction during operation period, we’ll offer you satisfied answer in time. We’ll reply you within 1 hour and provide solution or send staff to spot within 24 hours after receiving maintenance notification;

- Lifelong free technical support. Conduct satisfaction survey and inquiry equipment running condition to clients by telephone or e-mail semiannually from the first day of equipment running, put on records of acquired information;

- Provide assistance in solving problems such as equipment damage in the transport.

[title style=”center” text=”Send Message” color=”rgba(32, 163, 219, 0.81)”]

Error: Contact form not found.

Reviews

There are no reviews yet.